An Article to Help You Understand What Capacitors Are

I. Introduction

Capacitors are fundamental components in the world of electronics, playing a crucial role in various electrical circuits. They are essential for storing and releasing electrical energy, making them indispensable in a wide range of applications, from power supply systems to signal processing. This article aims to provide a comprehensive understanding of capacitors, their types, functions, applications, and future trends in technology.

II. What is a Capacitor?

A capacitor is a passive electronic component that stores electrical energy in an electric field. It consists of two conductive plates separated by an insulating material known as a dielectric. When a voltage is applied across the plates, an electric field is created, allowing the capacitor to store energy. The basic function of a capacitor is to store and release electrical energy, which can be utilized in various applications.

A. Basic Definition and Function

At its core, a capacitor is designed to hold an electrical charge. When connected to a power source, it accumulates charge on its plates, and when disconnected, it can release that charge back into the circuit. This ability to store and release energy makes capacitors vital in many electronic devices.

B. Components of a Capacitor

1. **Plates**: The conductive plates are typically made of metal and are responsible for holding the electric charge. The surface area of these plates directly affects the capacitance value.

2. **Dielectric Material**: The dielectric is the insulating material that separates the plates. It can be made from various materials, including ceramic, plastic, or electrolytic substances. The type of dielectric used influences the capacitor's performance and characteristics.

C. How Capacitors Store Energy

Capacitors store energy in the form of an electric field created between the plates when a voltage is applied. The amount of energy stored is proportional to the capacitance and the square of the voltage applied. This relationship is described by the formula:

\[ E = \frac{1}{2} C V^2 \]

where \( E \) is the energy stored, \( C \) is the capacitance, and \( V \) is the voltage.

III. Types of Capacitors

Capacitors come in various types, each designed for specific applications and performance characteristics. Understanding these types is essential for selecting the right capacitor for a given task.

A. Fixed Capacitors

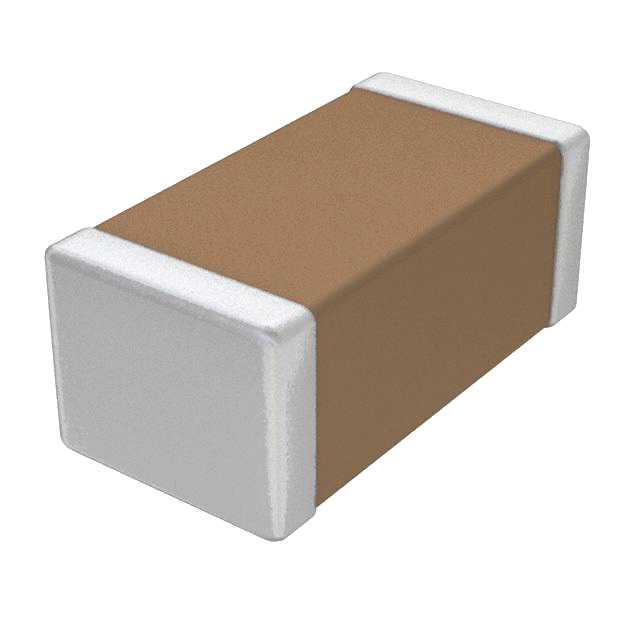

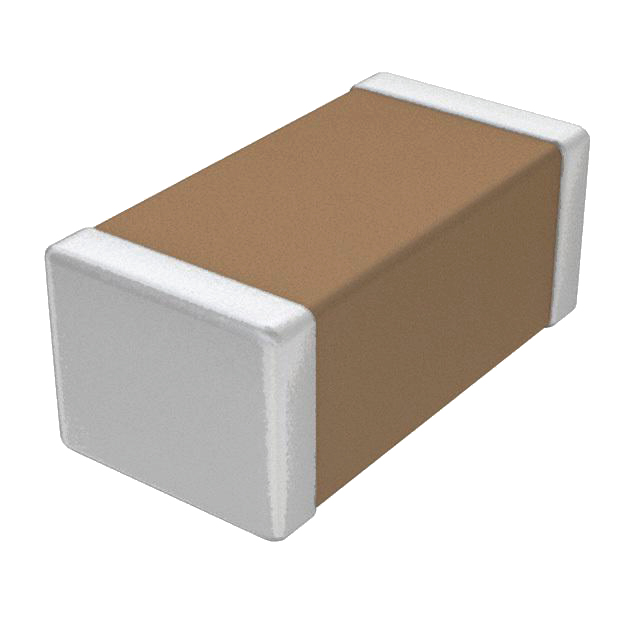

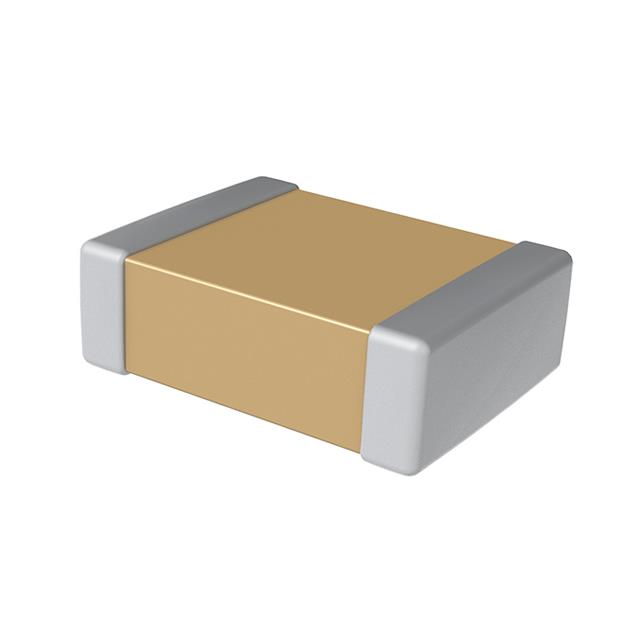

1. **Ceramic Capacitors**: These are widely used due to their small size, low cost, and stability. They are suitable for high-frequency applications and are often found in decoupling and filtering circuits.

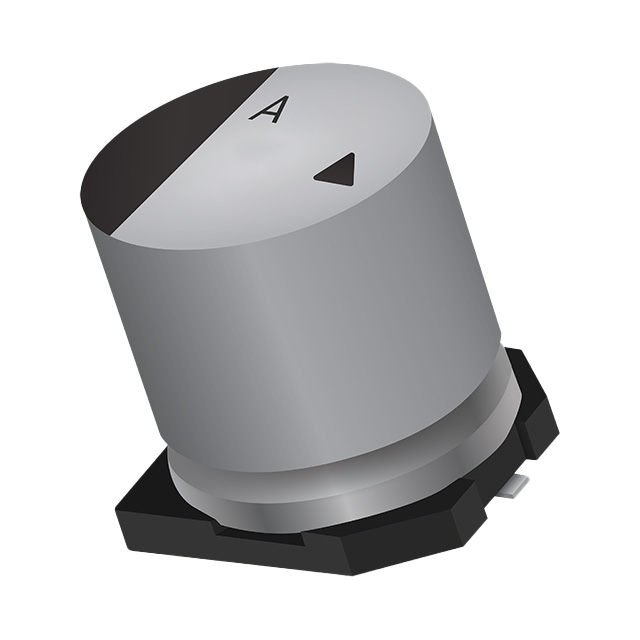

2. **Electrolytic Capacitors**: Known for their high capacitance values, electrolytic capacitors are polarized and typically used in power supply circuits. They are essential for smoothing out voltage fluctuations.

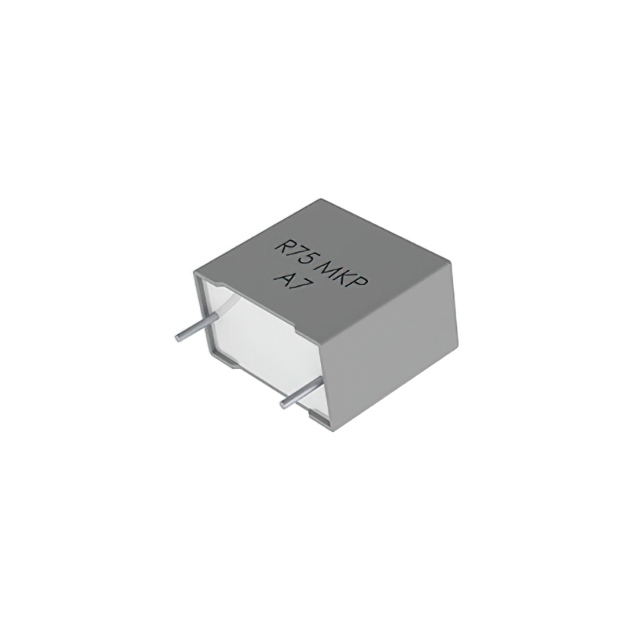

3. **Film Capacitors**: These capacitors use a thin plastic film as the dielectric. They are known for their stability and low loss, making them ideal for audio and high-frequency applications.

B. Variable Capacitors

1. **Tuning Capacitors**: These capacitors allow for adjustable capacitance, making them useful in radio frequency applications where tuning is necessary.

2. **Trimmer Capacitors**: Similar to tuning capacitors, trimmer capacitors are used for fine-tuning circuits and are often found in oscillators and filters.

C. Supercapacitors

Supercapacitors, also known as ultracapacitors, have extremely high capacitance values and can store large amounts of energy. They are used in applications requiring rapid charge and discharge cycles, such as energy storage systems and backup power supplies.

D. Specialty Capacitors

1. **Mica Capacitors**: These capacitors are known for their high stability and low loss, making them suitable for precision applications.

2. **Tantalum Capacitors**: Tantalum capacitors offer high capacitance in a small package and are often used in portable electronics and military applications.

IV. How Capacitors Work

A. The Principle of Capacitance

1. **Definition of Capacitance**: Capacitance is defined as the ability of a capacitor to store charge per unit voltage. It is measured in farads (F), with common subunits being microfarads (µF) and picofarads (pF).

2. **Formula for Capacitance**: The capacitance \( C \) can be calculated using the formula:

\[ C = \frac{Q}{V} \]

where \( Q \) is the charge stored and \( V \) is the voltage across the capacitor.

B. Charging and Discharging Process

When a capacitor is connected to a voltage source, it begins to charge, accumulating charge on its plates. The charging process follows an exponential curve, where the voltage across the capacitor increases until it reaches the supply voltage. When the capacitor is disconnected from the power source and connected to a load, it discharges, releasing its stored energy.

C. Time Constant and Its Significance

The time constant (\( \tau \)) of a capacitor is a measure of how quickly it charges and discharges. It is defined as:

\[ \tau = R \times C \]

where \( R \) is the resistance in the circuit. The time constant indicates the time it takes for the voltage across the capacitor to reach approximately 63.2% of its final value during charging or to drop to about 36.8% during discharging.

V. Applications of Capacitors

Capacitors are used in a wide range of applications, showcasing their versatility and importance in modern electronics.

A. In Power Supply Circuits

Capacitors are essential in power supply circuits for smoothing out voltage fluctuations and providing stable power to electronic devices. They help filter out noise and ensure a steady voltage supply.

B. In Signal Processing

In signal processing, capacitors are used in filters to block or pass specific frequency ranges. They play a crucial role in audio equipment, radio transmitters, and receivers.

C. In Timing Applications

Capacitors are integral to timing circuits, such as oscillators and timers. They work in conjunction with resistors to create time delays and generate clock signals.

D. In Energy Storage Systems

Supercapacitors are increasingly used in energy storage systems, providing rapid charge and discharge capabilities. They are ideal for applications like regenerative braking in electric vehicles and backup power systems.

E. In Filtering Applications

Capacitors are used in various filtering applications to remove unwanted frequencies from signals. They are commonly found in audio equipment, power supplies, and communication systems.

VI. Key Parameters of Capacitors

When selecting a capacitor, several key parameters must be considered to ensure optimal performance.

A. Capacitance Value

The capacitance value indicates the amount of charge a capacitor can store. It is essential to choose a capacitor with the appropriate capacitance for the specific application.

B. Voltage Rating

The voltage rating specifies the maximum voltage a capacitor can handle without breaking down. Exceeding this rating can lead to failure or damage.

C. Equivalent Series Resistance (ESR)

ESR is a measure of the internal resistance of a capacitor, affecting its efficiency and performance. Low ESR is desirable for applications requiring high-frequency operation.

D. Temperature Coefficient

The temperature coefficient indicates how the capacitance value changes with temperature. It is crucial for applications where temperature variations are expected.

E. Lifetime and Reliability

The lifetime and reliability of a capacitor are essential factors, especially in critical applications. Manufacturers often provide ratings for expected lifespan and failure rates.

VII. Choosing the Right Capacitor

Selecting the right capacitor involves considering various factors to ensure it meets the application's requirements.

A. Factors to Consider

1. **Application Requirements**: Understand the specific needs of the circuit, including capacitance value, voltage rating, and frequency response.

2. **Environmental Conditions**: Consider the operating environment, including temperature, humidity, and potential exposure to chemicals.

B. Common Mistakes to Avoid

Avoid common mistakes such as selecting a capacitor with an insufficient voltage rating, overlooking ESR, or failing to account for temperature variations.

VIII. Future Trends in Capacitor Technology

As technology advances, so do capacitors. Several trends are shaping the future of capacitor technology.

A. Advancements in Materials

Research into new dielectric materials is leading to capacitors with improved performance, higher capacitance values, and better thermal stability.

B. Innovations in Energy Storage

The development of supercapacitors and hybrid energy storage systems is paving the way for more efficient energy storage solutions, particularly in renewable energy applications.

C. The Role of Capacitors in Renewable Energy Systems

Capacitors are becoming increasingly important in renewable energy systems, helping to stabilize power output and improve energy efficiency in solar and wind applications.

IX. Conclusion

Capacitors are vital components in modern electronics, playing a crucial role in energy storage, signal processing, and power supply systems. Understanding their types, functions, and applications is essential for anyone working in the field of electronics. As technology continues to evolve, capacitors will remain at the forefront of innovation, contributing to advancements in energy storage and renewable energy systems. We encourage readers to explore further and stay informed about the exciting developments in capacitor technology.

X. References

A. Suggested readings on capacitors and their applications.

B. Online resources for further learning, including educational websites and forums.

C. Industry standards and guidelines for capacitor selection and usage.

How Big is the Market Size for Capacitor Prices?

I. Introduction

Capacitors are fundamental components in electronic devices, serving as energy storage units that help regulate voltage and current. They play a crucial role in various applications, from consumer electronics to automotive systems, making them indispensable in modern technology. As the demand for electronic devices continues to rise, understanding the market size for capacitors and their prices becomes increasingly important for manufacturers, investors, and consumers alike. This blog post will explore the capacitor market, its growth trends, factors influencing prices, and regional dynamics.

II. Understanding the Capacitor Market

A. Types of Capacitors

Capacitors come in various types, each suited for specific applications:

1. **Ceramic Capacitors**: Known for their small size and reliability, ceramic capacitors are widely used in high-frequency applications.

2. **Electrolytic Capacitors**: These capacitors are polarized and typically used in power supply circuits due to their high capacitance values.

3. **Film Capacitors**: Made from plastic films, these capacitors are known for their stability and low losses, making them ideal for audio and RF applications.

4. **Tantalum Capacitors**: These capacitors offer high capacitance in a small package and are often used in portable electronics.

5. **Supercapacitors**: Also known as ultracapacitors, they store a large amount of energy and are used in applications requiring rapid charge and discharge cycles.

B. Applications of Capacitors

Capacitors find applications across various sectors:

1. **Consumer Electronics**: From smartphones to televisions, capacitors are essential for power management and signal processing.

2. **Automotive Industry**: Capacitors are used in electric vehicles for energy storage and in traditional vehicles for various electronic systems.

3. **Industrial Applications**: Capacitors are crucial in machinery and equipment for energy efficiency and power factor correction.

4. **Renewable Energy Systems**: In solar and wind energy systems, capacitors help manage energy storage and distribution.

5. **Telecommunications**: Capacitors are vital in communication devices for signal filtering and power supply stabilization.

III. Market Size and Growth Trends

A. Current Market Size of the Capacitor Industry

The global capacitor market has seen significant growth in recent years. As of 2023, the market is valued at approximately $25 billion, with projections indicating it could reach $35 billion by 2028. This growth is driven by the increasing demand for electronic devices and advancements in technology.

1. Global Market Valuation

The capacitor market is characterized by a diverse range of products and applications, contributing to its substantial valuation. The rise of electric vehicles and renewable energy systems has further fueled demand.

2. Regional Market Breakdown

The market is not uniform across regions. North America, Europe, and Asia-Pacific are the leading markets, with Asia-Pacific expected to witness the highest growth due to rapid industrialization and technological advancements.

B. Historical Growth Trends

1. Market Growth Over the Past Decade

Over the past decade, the capacitor market has experienced a compound annual growth rate (CAGR) of around 6%. This growth can be attributed to the proliferation of consumer electronics and the increasing complexity of electronic systems.

2. Factors Influencing Growth

Several factors have influenced the growth of the capacitor market, including technological advancements, the rise of electric vehicles, and the growing demand for renewable energy solutions.

C. Future Projections

1. Expected Growth Rates

The capacitor market is expected to continue its upward trajectory, with a projected CAGR of 7% from 2023 to 2028. This growth will be driven by innovations in capacitor technology and the increasing adoption of electric vehicles.

2. Emerging Markets and Opportunities

Emerging markets in Asia, Latin America, and Africa present significant opportunities for growth. As these regions develop their infrastructure and technology, the demand for capacitors is expected to rise.

IV. Factors Influencing Capacitor Prices

A. Raw Material Costs

1. Price Fluctuations of Materials

The prices of raw materials used in capacitor manufacturing, such as tantalum and aluminum, can fluctuate significantly. These fluctuations directly impact capacitor prices, making it essential for manufacturers to manage their supply chains effectively.

2. Impact of Supply Chain Disruptions

Recent global events, such as the COVID-19 pandemic, have highlighted the vulnerability of supply chains. Disruptions can lead to shortages of raw materials, driving up prices and affecting the overall capacitor market.

B. Technological Advancements

1. Innovations in Capacitor Design and Manufacturing

Technological advancements have led to the development of more efficient and compact capacitors. Innovations such as multilayer ceramic capacitors (MLCCs) have improved performance while reducing costs.

2. Influence of Miniaturization and Efficiency Improvements

As electronic devices become smaller and more efficient, the demand for compact capacitors has increased. This trend has led to the development of new materials and manufacturing techniques that enhance performance.

C. Demand and Supply Dynamics

1. Seasonal Demand Variations

The capacitor market experiences seasonal demand variations, particularly in the consumer electronics sector. Manufacturers must anticipate these fluctuations to optimize production and pricing strategies.

2. Impact of Global Economic Conditions

Global economic conditions, including inflation and trade policies, can significantly impact capacitor prices. Economic downturns may lead to reduced demand, while economic growth can drive prices higher.

V. Regional Analysis of Capacitor Prices

A. North America

1. Market Characteristics

North America is a mature market for capacitors, characterized by high demand for advanced electronic systems. The region is home to several leading manufacturers and a robust supply chain.

2. Key Players and Manufacturers

Major players in the North American capacitor market include Vishay Intertechnology, KEMET Corporation, and AVX Corporation, which dominate the market with their innovative products.

B. Europe

1. Market Trends and Dynamics

The European capacitor market is influenced by stringent regulations and a focus on sustainability. Manufacturers are increasingly investing in eco-friendly production methods.

2. Regulatory Influences

Regulatory frameworks in Europe, such as the RoHS directive, impact capacitor manufacturing and pricing, pushing companies to adopt greener practices.

C. Asia-Pacific

1. Rapid Growth and Demand

The Asia-Pacific region is experiencing rapid growth in the capacitor market, driven by increasing industrialization and the demand for consumer electronics.

2. Major Manufacturing Hubs

Countries like China, Japan, and South Korea are major manufacturing hubs for capacitors, contributing significantly to the global supply chain.

D. Latin America and Middle East & Africa

1. Emerging Markets and Potential Growth

Latin America and the Middle East & Africa are emerging markets with significant growth potential. As these regions develop their infrastructure, the demand for capacitors is expected to rise.

VI. Competitive Landscape

A. Key Players in the Capacitor Market

1. Overview of Major Manufacturers

The capacitor market is competitive, with several key players, including Murata Manufacturing, Nichicon Corporation, and Panasonic Corporation, leading the industry.

2. Market Share Analysis

Market share analysis reveals that a few companies dominate the market, but there is room for smaller players to innovate and capture niche segments.

B. Strategies Employed by Leading Companies

1. Mergers and Acquisitions

Leading companies are increasingly engaging in mergers and acquisitions to expand their product offerings and market reach.

2. Research and Development Investments

Investments in research and development are crucial for staying competitive in the capacitor market, as companies strive to innovate and improve their products.

3. Sustainability Initiatives

Sustainability is becoming a key focus for manufacturers, with many companies adopting eco-friendly practices to meet regulatory requirements and consumer demand.

VII. Challenges Facing the Capacitor Market

A. Supply Chain Issues

Supply chain disruptions remain a significant challenge for the capacitor market, affecting production and pricing.

B. Environmental Regulations

Stricter environmental regulations are pushing manufacturers to adapt their processes, which can impact costs and pricing strategies.

C. Competition from Alternative Technologies

The rise of alternative technologies, such as solid-state batteries, poses a challenge to the traditional capacitor market, requiring manufacturers to innovate continuously.

VIII. Conclusion

In summary, the capacitor market is a dynamic and growing sector, driven by technological advancements and increasing demand across various applications. Understanding the market size and the factors influencing capacitor prices is essential for stakeholders, including manufacturers, investors, and consumers. As the market continues to evolve, monitoring trends and adapting to changes will be crucial for success in this competitive landscape.

IX. References

- Academic journals

- Industry reports

- Market research publications

This blog post provides a comprehensive overview of the capacitor market, highlighting its size, growth trends, and the factors influencing prices. By understanding these dynamics, stakeholders can make informed decisions in this vital industry.

How Big is the Market Size of Capacitor Factories?

I. Introduction

Capacitors are fundamental components in the world of electronics, serving as energy storage devices that play a crucial role in the functionality of various electronic devices. From smartphones to electric vehicles, capacitors help regulate voltage, filter signals, and store energy, making them indispensable in modern technology. The factories that manufacture these components are vital to the electronics supply chain, ensuring a steady supply of capacitors to meet the growing demand across multiple industries. This article aims to explore the market size of capacitor factories, providing insights into current trends, growth projections, and the factors influencing this dynamic sector.

II. Overview of the Capacitor Market

A. Types of Capacitors

Capacitors come in various types, each designed for specific applications and performance characteristics:

1. **Ceramic Capacitors**: Widely used due to their small size and reliability, ceramic capacitors are commonly found in consumer electronics.

2. **Electrolytic Capacitors**: Known for their high capacitance values, these capacitors are often used in power supply circuits.

3. **Film Capacitors**: These capacitors are favored for their stability and low losses, making them suitable for audio and high-frequency applications.

4. **Tantalum Capacitors**: With a high capacitance-to-volume ratio, tantalum capacitors are used in compact electronic devices.

5. **Supercapacitors**: These are used for energy storage applications, providing quick bursts of energy and high cycle stability.

B. Applications of Capacitors

Capacitors find applications across a wide range of industries:

1. **Consumer Electronics**: Smartphones, tablets, and laptops rely heavily on capacitors for efficient operation.

2. **Automotive Industry**: Capacitors are essential in electric vehicles for energy storage and management systems.

3. **Industrial Applications**: Used in machinery and automation systems, capacitors help improve efficiency and reliability.

4. **Renewable Energy Systems**: Capacitors play a critical role in energy storage solutions for solar and wind power systems.

5. **Telecommunications**: Capacitors are vital in signal processing and power management in communication devices.

III. Market Size and Growth Trends

A. Current Market Size of the Global Capacitor Industry

As of 2023, the global capacitor market is estimated to be valued at approximately $30 billion, with projections indicating continued growth. Key regions contributing to this market size include North America, Europe, and Asia-Pacific, with Asia-Pacific being the largest market due to the presence of major electronics manufacturers.

B. Historical Growth Trends

Historically, the capacitor market has experienced steady growth, driven by advancements in technology and increasing demand from various sectors. The rise of consumer electronics and the automotive industry's shift towards electric vehicles have significantly influenced market performance. Factors such as the miniaturization of electronic components and the demand for more efficient energy storage solutions have also contributed to this growth.

C. Future Projections

Looking ahead, the capacitor market is expected to grow at a compound annual growth rate (CAGR) of around 6% over the next five years. Emerging markets, particularly in Asia and Africa, present significant opportunities for expansion, driven by increasing urbanization and technological adoption.

IV. Factors Influencing Market Size

A. Technological Advancements

Technological innovations play a crucial role in shaping the capacitor market. Advances in capacitor design and materials have led to the development of more efficient and compact capacitors. The trend towards miniaturization in electronics has further fueled demand for smaller, high-performance capacitors.

B. Demand from End-User Industries

The growth of consumer electronics, electric vehicles, and renewable energy systems has created a surge in demand for capacitors. As these industries expand, the need for reliable and efficient energy storage solutions continues to rise, driving capacitor manufacturers to innovate and scale production.

C. Regulatory and Environmental Considerations

Regulatory compliance and sustainability trends are increasingly influencing the capacitor manufacturing landscape. Manufacturers are required to adhere to international standards, which can impact production processes and costs. Additionally, the push for sustainable manufacturing practices is prompting companies to explore eco-friendly materials and production methods.

V. Competitive Landscape

A. Key Players in the Capacitor Manufacturing Industry

The capacitor manufacturing industry is characterized by a mix of established players and emerging companies. Major companies include Murata Manufacturing, Vishay Intertechnology, and KEMET Corporation, which collectively hold a significant share of the market. These companies are known for their extensive product portfolios and strong research and development capabilities.

B. Strategies Employed by Leading Manufacturers

Leading manufacturers are employing various strategies to maintain their competitive edge. Mergers and acquisitions have become common as companies seek to expand their market presence and capabilities. Additionally, significant investments in research and development are being made to drive innovation and improve product offerings. Geographic expansion into emerging markets is also a key strategy for growth.

VI. Challenges Facing Capacitor Factories

A. Supply Chain Disruptions

Capacitor factories face challenges related to supply chain disruptions, particularly in the wake of global events such as pandemics and geopolitical tensions. These disruptions can lead to delays in production and increased costs, impacting overall market stability.

B. Raw Material Shortages

The availability and pricing of essential raw materials, such as tantalum and aluminum, pose significant challenges for capacitor manufacturers. Fluctuations in material costs can affect profit margins and production capabilities.

C. Competition from Alternative Technologies

The rise of alternative energy storage solutions, such as lithium-ion batteries and other advanced technologies, presents competition for traditional capacitors. Manufacturers must continuously innovate to remain relevant in a rapidly evolving market.

VII. Conclusion

In summary, the market size of capacitor factories is substantial and poised for growth, driven by technological advancements, increasing demand from various industries, and the need for efficient energy storage solutions. As the electronics landscape continues to evolve, capacitors will remain a critical component in the development of new technologies. The future outlook for capacitor factories is promising, with opportunities for expansion in emerging markets and ongoing innovation in capacitor design and manufacturing processes.

VIII. References

A comprehensive list of sources and data used in this article would typically include industry reports, market research studies, and articles from reputable publications. For readers interested in further exploring the topic, suggested readings could include market analysis reports from firms like MarketsandMarkets, Grand View Research, and industry-specific journals.

---

This blog post provides a detailed exploration of the market size of capacitor factories, covering essential aspects such as types of capacitors, market trends, influencing factors, competitive landscape, and challenges. Each section is designed to offer insights into the dynamic nature of the capacitor industry, making it a valuable resource for readers interested in understanding this critical component of modern electronics.

Popular Models of Common Capacitor Voltages

I. Introduction

Capacitors are fundamental components in electronic circuits, serving as energy storage devices that can release energy when needed. They play a crucial role in various applications, from smoothing out voltage fluctuations in power supplies to filtering signals in audio equipment. Understanding the voltage ratings of capacitors is essential for selecting the right component for a specific application. This article will explore common capacitor voltages, their types, popular models, and factors influencing voltage selection.

II. Understanding Capacitor Voltage Ratings

A. Explanation of Voltage Rating

The voltage rating of a capacitor indicates the maximum voltage that can be applied across its terminals without risking failure. Exceeding this voltage can lead to dielectric breakdown, resulting in catastrophic failure, which may include leakage, explosion, or complete failure of the capacitor. Therefore, understanding voltage ratings is critical for ensuring the longevity and reliability of electronic devices.

B. Common Voltage Ratings in Capacitors

Capacitors are categorized based on their voltage ratings:

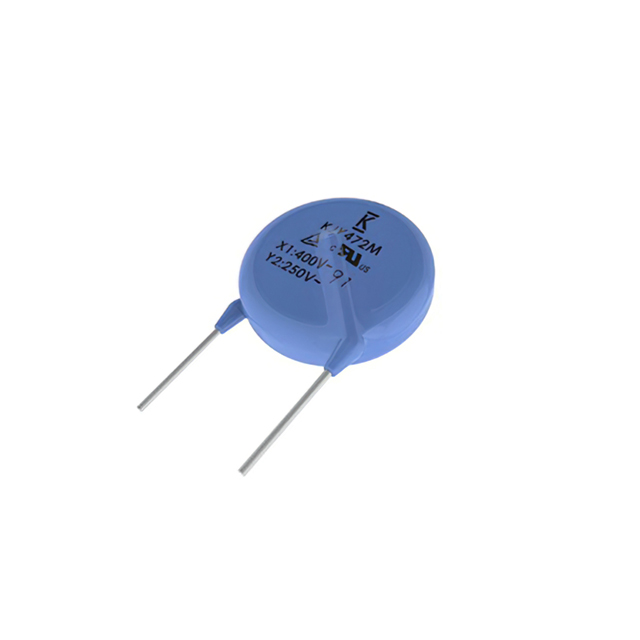

1. **Low Voltage (up to 50V)**: These capacitors are commonly used in low-power applications, such as consumer electronics and small signal circuits.

2. **Medium Voltage (50V to 250V)**: This range is typical for industrial applications, power supplies, and audio equipment.

3. **High Voltage (250V and above)**: High-voltage capacitors are used in specialized applications, including power transmission and high-frequency circuits.

III. Types of Capacitors and Their Voltage Ratings

A. Ceramic Capacitors

Ceramic capacitors are widely used due to their small size, low cost, and stability. They are available in various voltage ratings, typically ranging from 6.3V to 1000V. Common applications include decoupling, filtering, and timing circuits.

B. Electrolytic Capacitors

Electrolytic capacitors are polarized components known for their high capacitance values. They are commonly rated between 6.3V and 450V. These capacitors are often used in power supply circuits, audio amplifiers, and energy storage applications.

C. Film Capacitors

Film capacitors are known for their reliability and low loss characteristics. They typically have voltage ratings ranging from 50V to 1000V. Common applications include audio equipment, power electronics, and timing circuits.

D. Tantalum Capacitors

Tantalum capacitors are known for their high capacitance in a small package. They are usually rated between 6.3V and 50V. These capacitors are commonly used in portable electronics, medical devices, and military applications.

E. Supercapacitors

Supercapacitors, or ultracapacitors, are designed for high energy storage and rapid charge/discharge cycles. They typically have voltage ratings ranging from 2.5V to 5.5V. Common applications include energy storage systems, backup power supplies, and regenerative braking systems.

IV. Popular Models of Capacitors by Voltage Rating

A. Capacitors Rated for 10V to 50V

In this range, capacitors are often used in consumer electronics and low-power applications. Popular models include:

Panasonic ECQ Series: These film capacitors are known for their reliability and are available in various capacitance values.

Nichicon UHE Series: These electrolytic capacitors are designed for low impedance and high ripple current applications.

B. Capacitors Rated for 50V to 100V

Capacitors in this range are commonly used in power supplies and audio applications. Notable models include:

Kemet C4AE Series: These ceramic capacitors offer high capacitance and low ESR, making them suitable for power supply decoupling.

Rubycon ZLJ Series: These electrolytic capacitors are designed for high ripple current and long life, ideal for audio amplifiers.

C. Capacitors Rated for 100V to 250V

Capacitors in this category are often used in industrial applications. Popular models include:

WIMA MKS Series: These film capacitors are known for their high voltage ratings and stability, making them suitable for power electronics.

Nichicon PW Series: These electrolytic capacitors are designed for high performance in power supply applications.

D. Capacitors Rated for 250V and Above

High-voltage capacitors are used in specialized applications. Notable models include:

Vishay BC Components 193 Series: These film capacitors are designed for high voltage and high-frequency applications.

KEMET T520 Series: These tantalum capacitors are rated for high voltage and are used in military and aerospace applications.

V. Factors Influencing Capacitor Voltage Selection

A. Application Requirements

When selecting a capacitor, it is essential to consider the specific requirements of the application. This includes circuit design considerations, such as the maximum voltage the capacitor will experience, and load conditions, which can affect the capacitor's performance.

B. Environmental Factors

Environmental conditions, such as temperature and humidity, can significantly impact capacitor performance. High temperatures can reduce the lifespan of capacitors, while humidity can lead to corrosion and failure. Mechanical stress, such as vibration or shock, can also affect the reliability of capacitors.

C. Safety Margins

It is crucial to incorporate safety margins when selecting voltage ratings. Derating, or selecting a capacitor with a voltage rating higher than the maximum expected voltage, is a common practice to enhance reliability. Guidelines suggest derating by 20% to 50% to account for variations in operating conditions.

VI. Conclusion

Understanding capacitor voltage ratings is vital for selecting the right component for electronic applications. This article has explored the different types of capacitors, their voltage ratings, and popular models across various voltage ranges. By considering application requirements, environmental factors, and safety margins, engineers and designers can make informed decisions to ensure the reliability and longevity of their electronic devices.

VII. References

1. "Capacitor Basics: Types, Ratings, and Applications." Electronics Tutorials.

2. "Understanding Capacitor Voltage Ratings." Digi-Key Electronics.

3. Manufacturer datasheets for Panasonic, Nichicon, Kemet, Rubycon, Vishay, and KEMET capacitors.

By understanding the nuances of capacitor voltage ratings and the various models available, you can ensure that your electronic designs are both effective and reliable.