What are the Product Features of Pulse Capacitors?

I. Introduction

A. Definition of Pulse Capacitors

Pulse capacitors are specialized capacitors designed to handle high-energy pulses and rapid discharge cycles. Unlike standard capacitors, which may be optimized for steady-state applications, pulse capacitors are engineered to deliver high performance in applications that require quick bursts of energy. This makes them essential components in various high-demand environments.

B. Importance of Pulse Capacitors in Various Applications

The significance of pulse capacitors cannot be overstated. They play a crucial role in industries ranging from power electronics to telecommunications, automotive, and medical equipment. Their ability to manage high energy densities and rapid discharge rates makes them indispensable in applications where reliability and performance are paramount.

C. Overview of the Article

This article will delve into the fundamental principles of capacitors, explore the key features of pulse capacitors, discuss their construction and materials, and highlight their applications across different industries. Additionally, we will examine the advantages and challenges associated with using pulse capacitors, providing a comprehensive understanding of their role in modern technology.

II. Basic Principles of Capacitors

A. Explanation of Capacitor Functionality

Capacitors are passive electronic components that store and release electrical energy. They consist of two conductive plates separated by an insulating material known as a dielectric. When voltage is applied, an electric field forms between the plates, allowing the capacitor to store energy. When the voltage is removed, the capacitor can discharge this energy back into the circuit.

B. Types of Capacitors

Capacitors come in various types, each suited for specific applications:

1. **Electrolytic Capacitors**: Known for their high capacitance values, these capacitors are often used in power supply circuits.

2. **Ceramic Capacitors**: These are widely used for their stability and reliability in high-frequency applications.

3. **Film Capacitors**: Known for their low losses and high voltage ratings, film capacitors are used in audio and power applications.

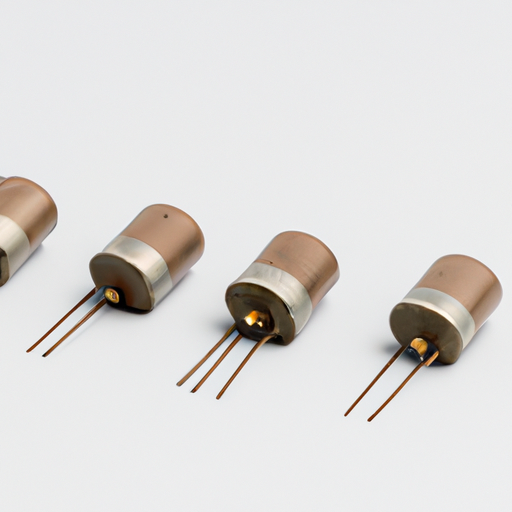

4. **Pulse Capacitors**: Specifically designed for high-energy pulse applications, these capacitors excel in delivering rapid bursts of energy.

III. Key Features of Pulse Capacitors

A. High Energy Density

1. Definition and Importance

High energy density refers to the amount of energy stored per unit volume or weight. Pulse capacitors are designed to maximize energy storage, making them ideal for applications that require significant power in a compact form.

2. Applications Requiring High Energy Density

Applications such as laser systems, pulsed power systems, and certain medical devices benefit from the high energy density of pulse capacitors, allowing for efficient energy storage and delivery.

B. Fast Discharge Rates

1. Explanation of Discharge Rates

Fast discharge rates indicate how quickly a capacitor can release its stored energy. Pulse capacitors are engineered to discharge energy rapidly, which is critical in applications that require immediate power delivery.

2. Impact on Performance in High-Pulse Applications

In high-pulse applications, such as inverters and converters, the ability to discharge quickly enhances overall system performance, ensuring that devices operate efficiently and reliably.

C. Low Equivalent Series Resistance (ESR)

1. Definition of ESR

Equivalent Series Resistance (ESR) is a measure of the resistive losses in a capacitor. Low ESR is crucial for pulse capacitors, as it minimizes energy loss during discharge.

2. Benefits of Low ESR in Pulse Applications

Low ESR allows pulse capacitors to deliver energy more efficiently, reducing heat generation and improving overall reliability in high-frequency applications.

D. High Voltage Ratings

1. Importance of Voltage Ratings

Pulse capacitors are designed to withstand high voltage levels, making them suitable for applications in power electronics and other high-voltage environments.

2. Applications in High-Voltage Environments

Industries such as telecommunications and power generation often require capacitors that can handle high voltage, and pulse capacitors meet these demands effectively.

E. Temperature Stability

1. Operating Temperature Range

Pulse capacitors are designed to operate effectively across a wide temperature range, ensuring consistent performance in varying environmental conditions.

2. Impact of Temperature on Performance

Temperature fluctuations can affect capacitor performance, but pulse capacitors are engineered to maintain stability, making them reliable in critical applications.

F. Long Cycle Life

1. Definition of Cycle Life

Cycle life refers to the number of charge and discharge cycles a capacitor can undergo before its performance degrades. Pulse capacitors are built for longevity, allowing them to endure repeated cycles without significant loss of performance.

2. Importance in Repetitive Pulse Applications

In applications such as welding and pulsed power systems, the long cycle life of pulse capacitors ensures that they can perform reliably over extended periods, reducing maintenance costs and downtime.

G. Compact Size and Lightweight Design

1. Advantages of Size and Weight

The compact and lightweight design of pulse capacitors makes them ideal for applications where space and weight are critical factors, such as in aerospace and portable devices.

2. Applications in Space-Constrained Environments

In industries like automotive and telecommunications, where space is often limited, pulse capacitors provide a solution without compromising performance.

IV. Construction and Materials

A. Dielectric Materials Used in Pulse Capacitors

1. Polypropylene

Polypropylene is a common dielectric material used in pulse capacitors due to its excellent electrical properties and stability under high temperatures.

2. Polyester

Polyester dielectrics offer good performance in a variety of applications, providing a balance between cost and efficiency.

3. Ceramic

Ceramic materials are used in pulse capacitors for their high dielectric strength and stability, making them suitable for high-frequency applications.

B. Manufacturing Techniques

1. Winding and Stacking Methods

Pulse capacitors are often manufactured using winding or stacking techniques, which help achieve the desired capacitance and performance characteristics.

2. Encapsulation and Sealing Processes

Proper encapsulation and sealing are essential to protect pulse capacitors from environmental factors, ensuring their longevity and reliability.

V. Applications of Pulse Capacitors

A. Power Electronics

1. Inverters and Converters

Pulse capacitors are widely used in inverters and converters, where they help manage energy flow and improve efficiency.

2. Power Supply Systems

In power supply systems, pulse capacitors provide the necessary energy storage to handle sudden demands for power.

B. Automotive Industry

1. Electric Vehicles

In electric vehicles, pulse capacitors are used to manage energy during acceleration and regenerative braking, enhancing overall performance.

2. Start-Stop Systems

Pulse capacitors play a crucial role in start-stop systems, providing quick bursts of energy to restart the engine efficiently.

C. Telecommunications

1. Signal Processing

In telecommunications, pulse capacitors are used in signal processing applications, ensuring reliable transmission of data.

2. RF Applications

Pulse capacitors are essential in radio frequency (RF) applications, where they help manage high-frequency signals.

D. Medical Equipment

1. Imaging Systems

In medical imaging systems, pulse capacitors provide the necessary energy for rapid imaging processes, improving diagnostic capabilities.

2. Therapeutic Devices

Pulse capacitors are also used in therapeutic devices, where they deliver precise energy pulses for treatment.

E. Industrial Applications

1. Welding Equipment

In welding equipment, pulse capacitors provide the high energy needed for effective welding processes.

2. Pulse Power Systems

Pulse capacitors are integral to pulse power systems, where they help manage energy delivery for various industrial applications.

VI. Advantages of Using Pulse Capacitors

A. Enhanced Performance in High-Pulse Applications

Pulse capacitors are specifically designed to excel in high-pulse applications, providing reliable performance and efficiency.

B. Reliability and Durability

The robust construction and materials used in pulse capacitors ensure long-lasting performance, even in demanding environments.

C. Cost-Effectiveness in Long-Term Use

While the initial cost of pulse capacitors may be higher, their durability and performance can lead to cost savings over time due to reduced maintenance and replacement needs.

D. Versatility Across Different Industries

Pulse capacitors are versatile components that find applications across various industries, making them a valuable addition to many electronic systems.

VII. Challenges and Considerations

A. Selection Criteria for Pulse Capacitors

1. Application Requirements

When selecting pulse capacitors, it is essential to consider the specific requirements of the application, including voltage, capacitance, and discharge rates.

2. Environmental Factors

Environmental factors such as temperature and humidity can impact capacitor performance, so it is crucial to choose capacitors that can withstand the operating conditions.

B. Potential Limitations

1. Size Constraints

While pulse capacitors are designed to be compact, certain applications may still face size constraints that limit their use.

2. Cost Considerations

The advanced technology and materials used in pulse capacitors can lead to higher costs, which may be a consideration for budget-sensitive projects.

VIII. Conclusion

A. Recap of Key Features and Benefits

Pulse capacitors offer a range of key features, including high energy density, fast discharge rates, low ESR, and long cycle life. These characteristics make them essential components in various high-demand applications.

B. Future Trends in Pulse Capacitor Technology

As technology continues to advance, we can expect further innovations in pulse capacitor design and materials, leading to even greater performance and efficiency.

C. Final Thoughts on the Importance of Pulse Capacitors in Modern Applications

In conclusion, pulse capacitors are vital components in modern electronic systems, providing the reliability and performance needed in a wide range of applications. Their unique features and capabilities make them indispensable in industries that demand high energy and rapid response times.

IX. References

A. Academic Journals

- Journal of Electrical Engineering

- IEEE Transactions on Power Electronics

B. Industry Reports

- Capacitor Market Analysis Report

- Trends in Power Electronics

C. Manufacturer Specifications and Data Sheets

- Manufacturer A: Pulse Capacitor Data Sheets

- Manufacturer B: Technical Specifications for Pulse Capacitors

---

This blog post provides a comprehensive overview of pulse capacitors, detailing their features, applications, and significance in modern technology. By understanding these components, readers can appreciate their role in enhancing performance across various industries.

What are the Product Features of Pulse Capacitors?

I. Introduction

A. Definition of Pulse Capacitors

Pulse capacitors are specialized capacitors designed to handle high-energy pulses and rapid discharge cycles. Unlike standard capacitors, which may be optimized for steady-state applications, pulse capacitors are engineered to deliver high performance in applications that require quick bursts of energy. This makes them essential components in various high-demand environments.

B. Importance of Pulse Capacitors in Various Applications

The significance of pulse capacitors cannot be overstated. They play a crucial role in industries ranging from power electronics to telecommunications, automotive, and medical equipment. Their ability to manage high energy densities and rapid discharge rates makes them indispensable in applications where reliability and performance are paramount.

C. Overview of the Article

This article will delve into the fundamental principles of capacitors, explore the key features of pulse capacitors, discuss their construction and materials, and highlight their applications across different industries. Additionally, we will examine the advantages and challenges associated with using pulse capacitors, providing a comprehensive understanding of their role in modern technology.

II. Basic Principles of Capacitors

A. Explanation of Capacitor Functionality

Capacitors are passive electronic components that store and release electrical energy. They consist of two conductive plates separated by an insulating material known as a dielectric. When voltage is applied, an electric field forms between the plates, allowing the capacitor to store energy. When the voltage is removed, the capacitor can discharge this energy back into the circuit.

B. Types of Capacitors

Capacitors come in various types, each suited for specific applications:

1. **Electrolytic Capacitors**: Known for their high capacitance values, these capacitors are often used in power supply circuits.

2. **Ceramic Capacitors**: These are widely used for their stability and reliability in high-frequency applications.

3. **Film Capacitors**: Known for their low losses and high voltage ratings, film capacitors are used in audio and power applications.

4. **Pulse Capacitors**: Specifically designed for high-energy pulse applications, these capacitors excel in delivering rapid bursts of energy.

III. Key Features of Pulse Capacitors

A. High Energy Density

1. Definition and Importance

High energy density refers to the amount of energy stored per unit volume or weight. Pulse capacitors are designed to maximize energy storage, making them ideal for applications that require significant power in a compact form.

2. Applications Requiring High Energy Density

Applications such as laser systems, pulsed power systems, and certain medical devices benefit from the high energy density of pulse capacitors, allowing for efficient energy storage and delivery.

B. Fast Discharge Rates

1. Explanation of Discharge Rates

Fast discharge rates indicate how quickly a capacitor can release its stored energy. Pulse capacitors are engineered to discharge energy rapidly, which is critical in applications that require immediate power delivery.

2. Impact on Performance in High-Pulse Applications

In high-pulse applications, such as inverters and converters, the ability to discharge quickly enhances overall system performance, ensuring that devices operate efficiently and reliably.

C. Low Equivalent Series Resistance (ESR)

1. Definition of ESR

Equivalent Series Resistance (ESR) is a measure of the resistive losses in a capacitor. Low ESR is crucial for pulse capacitors, as it minimizes energy loss during discharge.

2. Benefits of Low ESR in Pulse Applications

Low ESR allows pulse capacitors to deliver energy more efficiently, reducing heat generation and improving overall reliability in high-frequency applications.

D. High Voltage Ratings

1. Importance of Voltage Ratings

Pulse capacitors are designed to withstand high voltage levels, making them suitable for applications in power electronics and other high-voltage environments.

2. Applications in High-Voltage Environments

Industries such as telecommunications and power generation often require capacitors that can handle high voltage, and pulse capacitors meet these demands effectively.

E. Temperature Stability

1. Operating Temperature Range

Pulse capacitors are designed to operate effectively across a wide temperature range, ensuring consistent performance in varying environmental conditions.

2. Impact of Temperature on Performance

Temperature fluctuations can affect capacitor performance, but pulse capacitors are engineered to maintain stability, making them reliable in critical applications.

F. Long Cycle Life

1. Definition of Cycle Life

Cycle life refers to the number of charge and discharge cycles a capacitor can undergo before its performance degrades. Pulse capacitors are built for longevity, allowing them to endure repeated cycles without significant loss of performance.

2. Importance in Repetitive Pulse Applications

In applications such as welding and pulsed power systems, the long cycle life of pulse capacitors ensures that they can perform reliably over extended periods, reducing maintenance costs and downtime.

G. Compact Size and Lightweight Design

1. Advantages of Size and Weight

The compact and lightweight design of pulse capacitors makes them ideal for applications where space and weight are critical factors, such as in aerospace and portable devices.

2. Applications in Space-Constrained Environments

In industries like automotive and telecommunications, where space is often limited, pulse capacitors provide a solution without compromising performance.

IV. Construction and Materials

A. Dielectric Materials Used in Pulse Capacitors

1. Polypropylene

Polypropylene is a common dielectric material used in pulse capacitors due to its excellent electrical properties and stability under high temperatures.

2. Polyester

Polyester dielectrics offer good performance in a variety of applications, providing a balance between cost and efficiency.

3. Ceramic

Ceramic materials are used in pulse capacitors for their high dielectric strength and stability, making them suitable for high-frequency applications.

B. Manufacturing Techniques

1. Winding and Stacking Methods

Pulse capacitors are often manufactured using winding or stacking techniques, which help achieve the desired capacitance and performance characteristics.

2. Encapsulation and Sealing Processes

Proper encapsulation and sealing are essential to protect pulse capacitors from environmental factors, ensuring their longevity and reliability.

V. Applications of Pulse Capacitors

A. Power Electronics

1. Inverters and Converters

Pulse capacitors are widely used in inverters and converters, where they help manage energy flow and improve efficiency.

2. Power Supply Systems

In power supply systems, pulse capacitors provide the necessary energy storage to handle sudden demands for power.

B. Automotive Industry

1. Electric Vehicles

In electric vehicles, pulse capacitors are used to manage energy during acceleration and regenerative braking, enhancing overall performance.

2. Start-Stop Systems

Pulse capacitors play a crucial role in start-stop systems, providing quick bursts of energy to restart the engine efficiently.

C. Telecommunications

1. Signal Processing

In telecommunications, pulse capacitors are used in signal processing applications, ensuring reliable transmission of data.

2. RF Applications

Pulse capacitors are essential in radio frequency (RF) applications, where they help manage high-frequency signals.

D. Medical Equipment

1. Imaging Systems

In medical imaging systems, pulse capacitors provide the necessary energy for rapid imaging processes, improving diagnostic capabilities.

2. Therapeutic Devices

Pulse capacitors are also used in therapeutic devices, where they deliver precise energy pulses for treatment.

E. Industrial Applications

1. Welding Equipment

In welding equipment, pulse capacitors provide the high energy needed for effective welding processes.

2. Pulse Power Systems

Pulse capacitors are integral to pulse power systems, where they help manage energy delivery for various industrial applications.

VI. Advantages of Using Pulse Capacitors

A. Enhanced Performance in High-Pulse Applications

Pulse capacitors are specifically designed to excel in high-pulse applications, providing reliable performance and efficiency.

B. Reliability and Durability

The robust construction and materials used in pulse capacitors ensure long-lasting performance, even in demanding environments.

C. Cost-Effectiveness in Long-Term Use

While the initial cost of pulse capacitors may be higher, their durability and performance can lead to cost savings over time due to reduced maintenance and replacement needs.

D. Versatility Across Different Industries

Pulse capacitors are versatile components that find applications across various industries, making them a valuable addition to many electronic systems.

VII. Challenges and Considerations

A. Selection Criteria for Pulse Capacitors

1. Application Requirements

When selecting pulse capacitors, it is essential to consider the specific requirements of the application, including voltage, capacitance, and discharge rates.

2. Environmental Factors

Environmental factors such as temperature and humidity can impact capacitor performance, so it is crucial to choose capacitors that can withstand the operating conditions.

B. Potential Limitations

1. Size Constraints

While pulse capacitors are designed to be compact, certain applications may still face size constraints that limit their use.

2. Cost Considerations

The advanced technology and materials used in pulse capacitors can lead to higher costs, which may be a consideration for budget-sensitive projects.

VIII. Conclusion

A. Recap of Key Features and Benefits

Pulse capacitors offer a range of key features, including high energy density, fast discharge rates, low ESR, and long cycle life. These characteristics make them essential components in various high-demand applications.

B. Future Trends in Pulse Capacitor Technology

As technology continues to advance, we can expect further innovations in pulse capacitor design and materials, leading to even greater performance and efficiency.

C. Final Thoughts on the Importance of Pulse Capacitors in Modern Applications

In conclusion, pulse capacitors are vital components in modern electronic systems, providing the reliability and performance needed in a wide range of applications. Their unique features and capabilities make them indispensable in industries that demand high energy and rapid response times.

IX. References

A. Academic Journals

- Journal of Electrical Engineering

- IEEE Transactions on Power Electronics

B. Industry Reports

- Capacitor Market Analysis Report

- Trends in Power Electronics

C. Manufacturer Specifications and Data Sheets

- Manufacturer A: Pulse Capacitor Data Sheets

- Manufacturer B: Technical Specifications for Pulse Capacitors

---

This blog post provides a comprehensive overview of pulse capacitors, detailing their features, applications, and significance in modern technology. By understanding these components, readers can appreciate their role in enhancing performance across various industries.