What Product Types Do Guangzhou Inductors Include?

I. Introduction

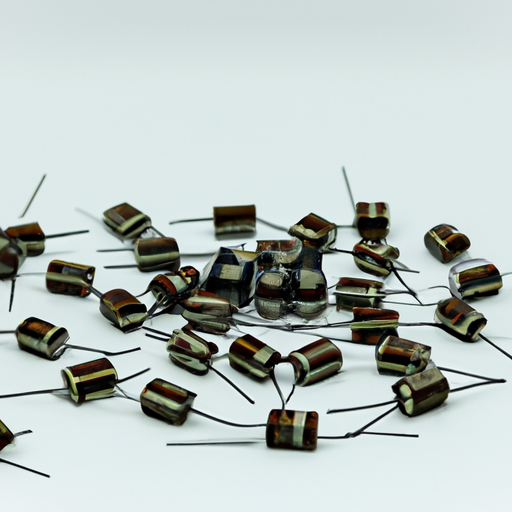

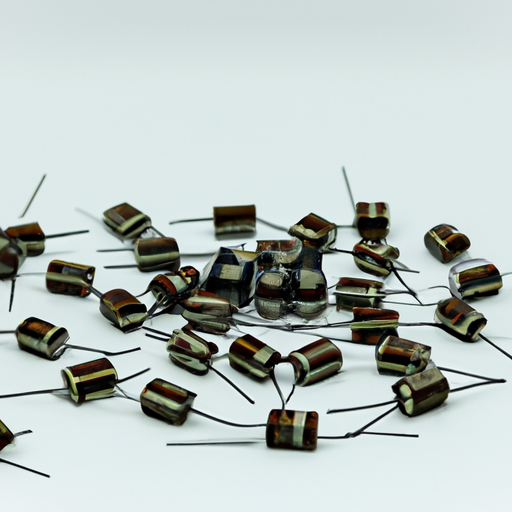

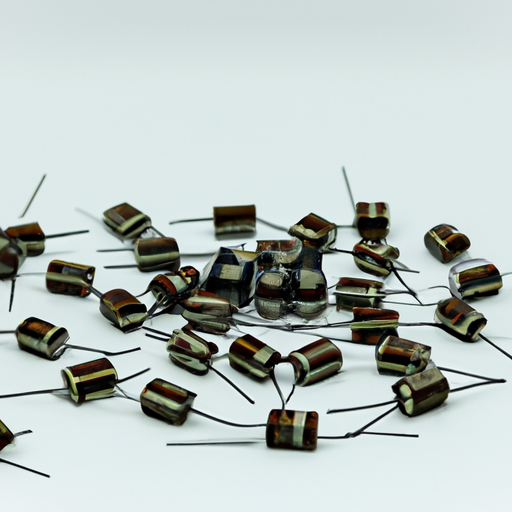

Inductors are passive electronic components that store energy in a magnetic field when electrical current flows through them. They play a crucial role in various electronic circuits, serving functions such as filtering, energy storage, and signal processing. As technology advances, the demand for high-quality inductors has surged, making cities like Guangzhou significant hubs for inductor manufacturing. This blog post will explore the various types of inductors produced in Guangzhou, their characteristics, applications, and the manufacturing landscape that supports this thriving industry.

II. Types of Inductors Manufactured in Guangzhou

Guangzhou is home to a diverse range of inductor types, each designed to meet specific needs in electronic applications. Below are the primary categories of inductors manufactured in the region:

A. Air Core Inductors

**Definition and Characteristics**

Air core inductors are inductors that do not use a magnetic core material. Instead, they rely on air as the medium for magnetic flux. This design results in low inductance values and high-frequency performance, making them suitable for specific applications.

**Applications and Advantages**

Air core inductors are commonly used in radio frequency (RF) applications, such as antennas and RF amplifiers. Their primary advantage is the minimal core losses, which allows for efficient operation at high frequencies. Additionally, they are less susceptible to saturation compared to core-based inductors.

B. Iron Core Inductors

**Definition and Characteristics**

Iron core inductors utilize an iron core to enhance the magnetic field generated by the coil. This design increases the inductance value and allows for more compact designs.

**Applications and Advantages**

These inductors are widely used in power supply circuits and transformers. The primary advantage of iron core inductors is their ability to handle higher currents and voltages, making them ideal for applications requiring significant energy storage.

C. Ferrite Core Inductors

**Definition and Characteristics**

Ferrite core inductors use ferrite materials, which are ceramic compounds made from iron oxide and other metals. Ferrite cores provide high magnetic permeability, which enhances inductance while minimizing energy losses.

**Applications and Advantages**

Ferrite core inductors are commonly found in switch-mode power supplies, filters, and RF applications. Their advantages include high efficiency, low core losses, and the ability to operate at high frequencies, making them suitable for modern electronic devices.

D. Toroidal Inductors

**Definition and Characteristics**

Toroidal inductors are shaped like a doughnut, with the wire wound around a circular core. This design minimizes electromagnetic interference and enhances efficiency.

**Applications and Advantages**

These inductors are used in power supplies, audio equipment, and RF applications. The primary advantage of toroidal inductors is their compact size and reduced electromagnetic interference, making them ideal for sensitive electronic applications.

E. Choke Inductors

**Definition and Characteristics**

Choke inductors are designed to block high-frequency AC signals while allowing low-frequency DC signals to pass. They are typically used in power supply circuits to filter out unwanted noise.

**Applications and Advantages**

Choke inductors are commonly used in power supplies, audio equipment, and signal processing applications. Their ability to suppress high-frequency noise makes them essential for maintaining signal integrity in electronic circuits.

F. SMD (Surface Mount Device) Inductors

**Definition and Characteristics**

SMD inductors are designed for surface mounting on printed circuit boards (PCBs). They are compact and lightweight, making them suitable for modern electronic devices.

**Applications and Advantages**

These inductors are widely used in smartphones, tablets, and other compact electronic devices. Their primary advantage is the space-saving design, which allows for more efficient use of PCB real estate.

G. Power Inductors

**Definition and Characteristics**

Power inductors are designed to handle high current levels and are typically used in power management applications. They often feature a magnetic core to enhance inductance.

**Applications and Advantages**

Power inductors are commonly found in DC-DC converters, power supplies, and energy storage applications. Their ability to handle high currents makes them essential for efficient power management in electronic devices.

H. High-Frequency Inductors

**Definition and Characteristics**

High-frequency inductors are designed to operate efficiently at elevated frequencies, often exceeding several megahertz. They are typically constructed with materials that minimize losses at these frequencies.

**Applications and Advantages**

These inductors are used in RF applications, telecommunications, and high-speed data transmission. Their primary advantage is the ability to maintain performance at high frequencies, making them crucial for modern communication technologies.

III. Specialized Inductors

In addition to the standard types of inductors, Guangzhou manufacturers also produce specialized inductors tailored for specific industries and applications.

A. Custom Inductors

**Definition and Characteristics**

Custom inductors are designed to meet specific requirements of clients, including unique inductance values, sizes, and materials. These inductors are often produced in smaller quantities.

**Industries Served**

Custom inductors are used in various industries, including aerospace, medical devices, and industrial automation. Their tailored design allows for optimal performance in specialized applications.

B. Inductors for Automotive Applications

**Definition and Characteristics**

Inductors designed for automotive applications must meet stringent reliability and performance standards due to the demanding environment of vehicles.

**Importance in Automotive Electronics**

These inductors are crucial for power management, signal processing, and noise filtering in automotive electronics. Their reliability ensures the proper functioning of critical systems, such as engine control units and infotainment systems.

C. Inductors for Telecommunications

**Definition and Characteristics**

Telecommunications inductors are designed to support high-frequency signals and maintain signal integrity in communication devices.

**Role in Communication Devices**

These inductors are essential for filters, amplifiers, and other components in telecommunications equipment. Their ability to handle high frequencies and minimize losses is vital for efficient communication.

IV. Manufacturing Processes in Guangzhou

Guangzhou's inductor manufacturing industry is characterized by advanced processes and technologies that ensure high-quality products.

A. Overview of Manufacturing Capabilities

Manufacturers in Guangzhou utilize state-of-the-art machinery and techniques to produce a wide range of inductors. This includes automated winding machines, precision testing equipment, and advanced material handling systems.

B. Quality Control Measures

Quality control is a critical aspect of inductor manufacturing in Guangzhou. Manufacturers implement rigorous testing protocols to ensure that each inductor meets industry standards and customer specifications. This includes electrical testing, thermal testing, and mechanical inspections.

C. Technological Advancements in Production

The inductor manufacturing sector in Guangzhou is continually evolving, with advancements in materials and production techniques. Innovations such as improved core materials, automated production lines, and enhanced design software contribute to the efficiency and quality of inductor production.

V. Market Trends and Demand

The global demand for inductors is on the rise, driven by advancements in technology and the increasing complexity of electronic devices.

A. Global Demand for Inductors

As industries such as consumer electronics, automotive, and telecommunications expand, the demand for high-quality inductors continues to grow. Manufacturers in Guangzhou are well-positioned to meet this demand due to their extensive product range and manufacturing capabilities.

B. Emerging Technologies Influencing Inductor Design

Emerging technologies, such as electric vehicles, renewable energy systems, and IoT devices, are influencing inductor design. Manufacturers are adapting their products to meet the specific requirements of these technologies, leading to innovations in size, efficiency, and performance.

C. Future Outlook for the Inductor Market in Guangzhou

The future of the inductor market in Guangzhou looks promising, with continued investment in research and development, as well as a focus on sustainability and efficiency. As global demand for inductors increases, Guangzhou is likely to remain a key player in the industry.

VI. Conclusion

In summary, Guangzhou is a significant hub for inductor manufacturing, producing a diverse range of inductor types, including air core, iron core, ferrite core, toroidal, choke, SMD, power, and high-frequency inductors. The region's advanced manufacturing processes, quality control measures, and technological innovations contribute to its prominence in the global inductor market. As the demand for inductors continues to grow, Guangzhou is well-positioned to lead the way in the future of inductor manufacturing.

VII. References

- Academic articles and journals on inductor technology and applications.

- Industry reports detailing market trends and forecasts for inductors.

- Manufacturer websites and product catalogs for specific inductor types and specifications.

This comprehensive overview of the types of inductors produced in Guangzhou highlights the region's importance in the global electronics industry and its role in shaping the future of inductor technology.

What Product Types Do Guangzhou Inductors Include?

I. Introduction

Inductors are passive electronic components that store energy in a magnetic field when electrical current flows through them. They play a crucial role in various electronic circuits, serving functions such as filtering, energy storage, and signal processing. As technology advances, the demand for high-quality inductors has surged, making cities like Guangzhou significant hubs for inductor manufacturing. This blog post will explore the various types of inductors produced in Guangzhou, their characteristics, applications, and the manufacturing landscape that supports this thriving industry.

II. Types of Inductors Manufactured in Guangzhou

Guangzhou is home to a diverse range of inductor types, each designed to meet specific needs in electronic applications. Below are the primary categories of inductors manufactured in the region:

A. Air Core Inductors

**Definition and Characteristics**

Air core inductors are inductors that do not use a magnetic core material. Instead, they rely on air as the medium for magnetic flux. This design results in low inductance values and high-frequency performance, making them suitable for specific applications.

**Applications and Advantages**

Air core inductors are commonly used in radio frequency (RF) applications, such as antennas and RF amplifiers. Their primary advantage is the minimal core losses, which allows for efficient operation at high frequencies. Additionally, they are less susceptible to saturation compared to core-based inductors.

B. Iron Core Inductors

**Definition and Characteristics**

Iron core inductors utilize an iron core to enhance the magnetic field generated by the coil. This design increases the inductance value and allows for more compact designs.

**Applications and Advantages**

These inductors are widely used in power supply circuits and transformers. The primary advantage of iron core inductors is their ability to handle higher currents and voltages, making them ideal for applications requiring significant energy storage.

C. Ferrite Core Inductors

**Definition and Characteristics**

Ferrite core inductors use ferrite materials, which are ceramic compounds made from iron oxide and other metals. Ferrite cores provide high magnetic permeability, which enhances inductance while minimizing energy losses.

**Applications and Advantages**

Ferrite core inductors are commonly found in switch-mode power supplies, filters, and RF applications. Their advantages include high efficiency, low core losses, and the ability to operate at high frequencies, making them suitable for modern electronic devices.

D. Toroidal Inductors

**Definition and Characteristics**

Toroidal inductors are shaped like a doughnut, with the wire wound around a circular core. This design minimizes electromagnetic interference and enhances efficiency.

**Applications and Advantages**

These inductors are used in power supplies, audio equipment, and RF applications. The primary advantage of toroidal inductors is their compact size and reduced electromagnetic interference, making them ideal for sensitive electronic applications.

E. Choke Inductors

**Definition and Characteristics**

Choke inductors are designed to block high-frequency AC signals while allowing low-frequency DC signals to pass. They are typically used in power supply circuits to filter out unwanted noise.

**Applications and Advantages**

Choke inductors are commonly used in power supplies, audio equipment, and signal processing applications. Their ability to suppress high-frequency noise makes them essential for maintaining signal integrity in electronic circuits.

F. SMD (Surface Mount Device) Inductors

**Definition and Characteristics**

SMD inductors are designed for surface mounting on printed circuit boards (PCBs). They are compact and lightweight, making them suitable for modern electronic devices.

**Applications and Advantages**

These inductors are widely used in smartphones, tablets, and other compact electronic devices. Their primary advantage is the space-saving design, which allows for more efficient use of PCB real estate.

G. Power Inductors

**Definition and Characteristics**

Power inductors are designed to handle high current levels and are typically used in power management applications. They often feature a magnetic core to enhance inductance.

**Applications and Advantages**

Power inductors are commonly found in DC-DC converters, power supplies, and energy storage applications. Their ability to handle high currents makes them essential for efficient power management in electronic devices.

H. High-Frequency Inductors

**Definition and Characteristics**

High-frequency inductors are designed to operate efficiently at elevated frequencies, often exceeding several megahertz. They are typically constructed with materials that minimize losses at these frequencies.

**Applications and Advantages**

These inductors are used in RF applications, telecommunications, and high-speed data transmission. Their primary advantage is the ability to maintain performance at high frequencies, making them crucial for modern communication technologies.

III. Specialized Inductors

In addition to the standard types of inductors, Guangzhou manufacturers also produce specialized inductors tailored for specific industries and applications.

A. Custom Inductors

**Definition and Characteristics**

Custom inductors are designed to meet specific requirements of clients, including unique inductance values, sizes, and materials. These inductors are often produced in smaller quantities.

**Industries Served**

Custom inductors are used in various industries, including aerospace, medical devices, and industrial automation. Their tailored design allows for optimal performance in specialized applications.

B. Inductors for Automotive Applications

**Definition and Characteristics**

Inductors designed for automotive applications must meet stringent reliability and performance standards due to the demanding environment of vehicles.

**Importance in Automotive Electronics**

These inductors are crucial for power management, signal processing, and noise filtering in automotive electronics. Their reliability ensures the proper functioning of critical systems, such as engine control units and infotainment systems.

C. Inductors for Telecommunications

**Definition and Characteristics**

Telecommunications inductors are designed to support high-frequency signals and maintain signal integrity in communication devices.

**Role in Communication Devices**

These inductors are essential for filters, amplifiers, and other components in telecommunications equipment. Their ability to handle high frequencies and minimize losses is vital for efficient communication.

IV. Manufacturing Processes in Guangzhou

Guangzhou's inductor manufacturing industry is characterized by advanced processes and technologies that ensure high-quality products.

A. Overview of Manufacturing Capabilities

Manufacturers in Guangzhou utilize state-of-the-art machinery and techniques to produce a wide range of inductors. This includes automated winding machines, precision testing equipment, and advanced material handling systems.

B. Quality Control Measures

Quality control is a critical aspect of inductor manufacturing in Guangzhou. Manufacturers implement rigorous testing protocols to ensure that each inductor meets industry standards and customer specifications. This includes electrical testing, thermal testing, and mechanical inspections.

C. Technological Advancements in Production

The inductor manufacturing sector in Guangzhou is continually evolving, with advancements in materials and production techniques. Innovations such as improved core materials, automated production lines, and enhanced design software contribute to the efficiency and quality of inductor production.

V. Market Trends and Demand

The global demand for inductors is on the rise, driven by advancements in technology and the increasing complexity of electronic devices.

A. Global Demand for Inductors

As industries such as consumer electronics, automotive, and telecommunications expand, the demand for high-quality inductors continues to grow. Manufacturers in Guangzhou are well-positioned to meet this demand due to their extensive product range and manufacturing capabilities.

B. Emerging Technologies Influencing Inductor Design

Emerging technologies, such as electric vehicles, renewable energy systems, and IoT devices, are influencing inductor design. Manufacturers are adapting their products to meet the specific requirements of these technologies, leading to innovations in size, efficiency, and performance.

C. Future Outlook for the Inductor Market in Guangzhou

The future of the inductor market in Guangzhou looks promising, with continued investment in research and development, as well as a focus on sustainability and efficiency. As global demand for inductors increases, Guangzhou is likely to remain a key player in the industry.

VI. Conclusion

In summary, Guangzhou is a significant hub for inductor manufacturing, producing a diverse range of inductor types, including air core, iron core, ferrite core, toroidal, choke, SMD, power, and high-frequency inductors. The region's advanced manufacturing processes, quality control measures, and technological innovations contribute to its prominence in the global inductor market. As the demand for inductors continues to grow, Guangzhou is well-positioned to lead the way in the future of inductor manufacturing.

VII. References

- Academic articles and journals on inductor technology and applications.

- Industry reports detailing market trends and forecasts for inductors.

- Manufacturer websites and product catalogs for specific inductor types and specifications.

This comprehensive overview of the types of inductors produced in Guangzhou highlights the region's importance in the global electronics industry and its role in shaping the future of inductor technology.