Popular Magnetic Ring Inductor Models

I. Introduction

A. Definition of Magnetic Ring Inductors

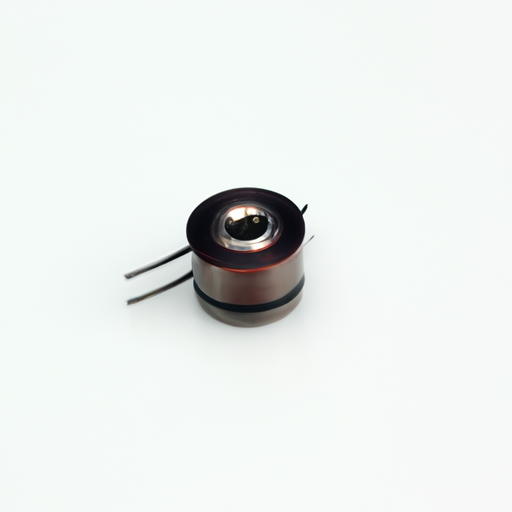

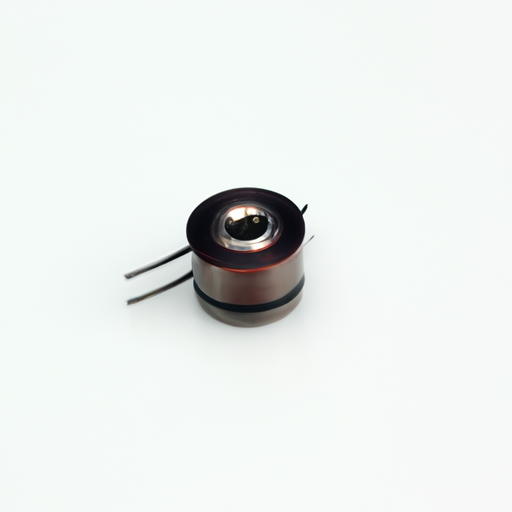

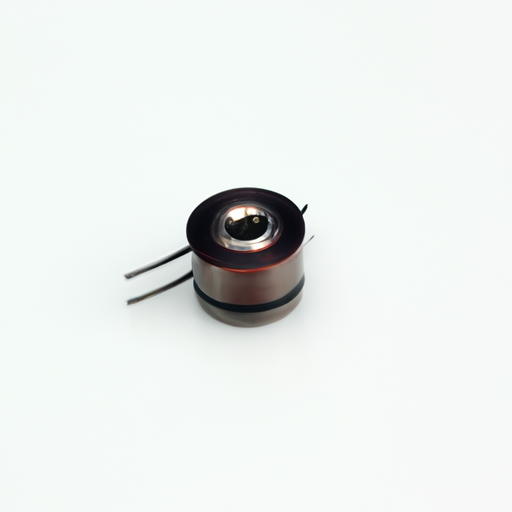

Magnetic ring inductors, also known as toroidal inductors, are passive electronic components that store energy in a magnetic field when electrical current flows through them. They are characterized by their ring-shaped core, which can be made from various materials, including ferrite, iron powder, and composite materials. The design of these inductors allows for efficient energy storage and minimal electromagnetic interference, making them essential in many electronic applications.

B. Importance of Magnetic Ring Inductors in Electronics

In the realm of electronics, magnetic ring inductors play a crucial role in various applications, including power supplies, radio frequency (RF) circuits, and signal filtering. Their ability to handle high currents and voltages while maintaining low losses makes them indispensable in modern electronic devices. As technology advances, the demand for efficient and compact inductors continues to grow, further highlighting the importance of magnetic ring inductors.

C. Overview of the Article

This article will delve into the basics of magnetic ring inductors, explore popular models available in the market, compare their performance, and discuss emerging trends in the technology. By the end, readers will have a comprehensive understanding of magnetic ring inductors and how to choose the right model for their applications.

II. Basics of Magnetic Ring Inductors

A. Structure and Functionality

1. Core Materials

The core material of a magnetic ring inductor significantly influences its performance. Common materials include ferrite, iron powder, and composite materials. Ferrite cores are known for their high magnetic permeability and low losses at high frequencies, making them ideal for RF applications. Iron powder cores, on the other hand, offer excellent saturation characteristics and are suitable for power applications. Composite materials combine the benefits of both ferrite and iron powder, providing a balance between performance and cost.

2. Winding Techniques

The winding technique used in magnetic ring inductors also affects their performance. Inductors can be wound with different configurations, such as single-layer or multi-layer windings. The choice of winding technique impacts the inductor's inductance value, DC resistance, and overall efficiency.

B. Key Parameters

1. Inductance

Inductance is a measure of an inductor's ability to store energy in a magnetic field. It is typically measured in henries (H) and is a critical parameter when selecting an inductor for a specific application.

2. Saturation Current

Saturation current refers to the maximum current an inductor can handle before its inductance begins to decrease significantly. Exceeding this current can lead to overheating and potential damage to the inductor.

3. DC Resistance

DC resistance is the resistance of the inductor when a direct current flows through it. Lower DC resistance is desirable as it leads to reduced power losses and improved efficiency.

C. Applications in Circuits

1. Power Supplies

Magnetic ring inductors are widely used in power supply circuits to filter out noise and stabilize voltage levels. They help ensure that the power delivered to electronic components is clean and reliable.

2. RF Applications

In RF circuits, magnetic ring inductors are used for impedance matching, filtering, and tuning. Their ability to operate efficiently at high frequencies makes them ideal for applications such as antennas and RF amplifiers.

3. Signal Filtering

Inductors are essential in signal filtering applications, where they help remove unwanted frequencies from signals. This is particularly important in audio and communication systems, where signal integrity is crucial.

III. Popular Magnetic Ring Inductor Models

A. Ferrite Core Inductors

1. Overview of Ferrite Materials

Ferrite materials are ceramic compounds made from iron oxide mixed with other metals. They exhibit high magnetic permeability and low electrical conductivity, making them suitable for high-frequency applications.

2. Notable Models

a. Fair-Rite Ferrite Cores

Fair-Rite is a well-known manufacturer of ferrite cores and inductors. Their products are widely used in various applications, including telecommunications and consumer electronics. Fair-Rite ferrite cores are known for their high quality and reliability.

b. TDK Ferrite Beads

TDK is another leading manufacturer of ferrite components. Their ferrite beads are commonly used for noise suppression in electronic circuits. TDK's ferrite beads are designed to provide excellent attenuation of high-frequency noise while maintaining low DC resistance.

B. Iron Powder Inductors

1. Characteristics of Iron Powder Cores

Iron powder cores are made from finely powdered iron particles that are compacted and sintered. They offer excellent saturation characteristics and are suitable for applications requiring high current handling.

2. Notable Models

a. Micrometals Iron Powder Cores

Micrometals is a prominent manufacturer of iron powder cores. Their products are known for their high efficiency and low losses, making them ideal for power supply applications.

b. Amidon Iron Powder Inductors

Amidon is another reputable manufacturer of iron powder inductors. Their inductors are widely used in RF applications and are known for their reliability and performance.

C. Composite Core Inductors

1. Benefits of Composite Materials

Composite core inductors combine the advantages of ferrite and iron powder materials. They offer improved performance in terms of saturation current and thermal stability, making them suitable for a wide range of applications.

2. Notable Models

a. EPCOS Composite Inductors

EPCOS, a subsidiary of TDK, produces a range of composite inductors known for their high efficiency and compact design. These inductors are widely used in power electronics and automotive applications.

b. Vishay Dale Composite Inductors

Vishay Dale is another leading manufacturer of composite inductors. Their products are known for their reliability and performance in demanding applications, including industrial and telecommunications.

IV. Comparison of Popular Models

A. Performance Metrics

1. Efficiency

Efficiency is a critical factor when comparing magnetic ring inductors. Higher efficiency means lower power losses, which is essential for applications where energy conservation is a priority.

2. Thermal Stability

Thermal stability is another important consideration. Inductors that can operate at higher temperatures without degradation in performance are preferred, especially in high-power applications.

B. Cost Considerations

Cost is always a factor in component selection. While high-performance inductors may come at a premium, the long-term benefits of efficiency and reliability can justify the investment.

C. Availability and Sourcing

Availability and sourcing are crucial for manufacturers. Popular models from reputable manufacturers are often easier to source, ensuring that production schedules are met without delays.

V. Trends in Magnetic Ring Inductor Technology

A. Advancements in Materials

Recent advancements in materials science have led to the development of new core materials that offer improved performance characteristics. These materials can enhance inductance values while reducing losses.

B. Miniaturization and Integration

As electronic devices become smaller and more compact, the trend towards miniaturization in inductors is becoming increasingly important. Manufacturers are developing smaller inductors that maintain high performance without compromising on efficiency.

C. Environmental Considerations

With growing awareness of environmental issues, manufacturers are focusing on producing inductors that are more environmentally friendly. This includes using sustainable materials and processes that reduce waste and energy consumption.

VI. Conclusion

A. Summary of Key Points

Magnetic ring inductors are essential components in modern electronics, offering efficient energy storage and minimal interference. Understanding the different types of inductors, their key parameters, and popular models can help engineers and designers make informed decisions.

B. Future Outlook for Magnetic Ring Inductors

The future of magnetic ring inductors looks promising, with ongoing advancements in materials and technology. As the demand for efficient and compact inductors continues to grow, manufacturers will likely focus on innovation to meet these needs.

C. Final Thoughts on Choosing the Right Inductor Model

When selecting a magnetic ring inductor, it is essential to consider factors such as inductance, saturation current, DC resistance, and application requirements. By understanding the various models available and their performance characteristics, designers can choose the right inductor for their specific needs.

VII. References

A. Academic Journals

- IEEE Transactions on Power Electronics

- Journal of Applied Physics

B. Industry Reports

- Market Research Reports on Inductor Technologies

- Industry Analysis on Passive Components

C. Manufacturer Specifications and Datasheets

- Fair-Rite Products Corp. Datasheets

- TDK Corporation Product Catalogs

This comprehensive exploration of magnetic ring inductors provides valuable insights into their importance, popular models, and future trends, equipping readers with the knowledge needed to make informed decisions in their electronic designs.

Popular Magnetic Ring Inductor Models

I. Introduction

A. Definition of Magnetic Ring Inductors

Magnetic ring inductors, also known as toroidal inductors, are passive electronic components that store energy in a magnetic field when electrical current flows through them. They are characterized by their ring-shaped core, which can be made from various materials, including ferrite, iron powder, and composite materials. The design of these inductors allows for efficient energy storage and minimal electromagnetic interference, making them essential in many electronic applications.

B. Importance of Magnetic Ring Inductors in Electronics

In the realm of electronics, magnetic ring inductors play a crucial role in various applications, including power supplies, radio frequency (RF) circuits, and signal filtering. Their ability to handle high currents and voltages while maintaining low losses makes them indispensable in modern electronic devices. As technology advances, the demand for efficient and compact inductors continues to grow, further highlighting the importance of magnetic ring inductors.

C. Overview of the Article

This article will delve into the basics of magnetic ring inductors, explore popular models available in the market, compare their performance, and discuss emerging trends in the technology. By the end, readers will have a comprehensive understanding of magnetic ring inductors and how to choose the right model for their applications.

II. Basics of Magnetic Ring Inductors

A. Structure and Functionality

1. Core Materials

The core material of a magnetic ring inductor significantly influences its performance. Common materials include ferrite, iron powder, and composite materials. Ferrite cores are known for their high magnetic permeability and low losses at high frequencies, making them ideal for RF applications. Iron powder cores, on the other hand, offer excellent saturation characteristics and are suitable for power applications. Composite materials combine the benefits of both ferrite and iron powder, providing a balance between performance and cost.

2. Winding Techniques

The winding technique used in magnetic ring inductors also affects their performance. Inductors can be wound with different configurations, such as single-layer or multi-layer windings. The choice of winding technique impacts the inductor's inductance value, DC resistance, and overall efficiency.

B. Key Parameters

1. Inductance

Inductance is a measure of an inductor's ability to store energy in a magnetic field. It is typically measured in henries (H) and is a critical parameter when selecting an inductor for a specific application.

2. Saturation Current

Saturation current refers to the maximum current an inductor can handle before its inductance begins to decrease significantly. Exceeding this current can lead to overheating and potential damage to the inductor.

3. DC Resistance

DC resistance is the resistance of the inductor when a direct current flows through it. Lower DC resistance is desirable as it leads to reduced power losses and improved efficiency.

C. Applications in Circuits

1. Power Supplies

Magnetic ring inductors are widely used in power supply circuits to filter out noise and stabilize voltage levels. They help ensure that the power delivered to electronic components is clean and reliable.

2. RF Applications

In RF circuits, magnetic ring inductors are used for impedance matching, filtering, and tuning. Their ability to operate efficiently at high frequencies makes them ideal for applications such as antennas and RF amplifiers.

3. Signal Filtering

Inductors are essential in signal filtering applications, where they help remove unwanted frequencies from signals. This is particularly important in audio and communication systems, where signal integrity is crucial.

III. Popular Magnetic Ring Inductor Models

A. Ferrite Core Inductors

1. Overview of Ferrite Materials

Ferrite materials are ceramic compounds made from iron oxide mixed with other metals. They exhibit high magnetic permeability and low electrical conductivity, making them suitable for high-frequency applications.

2. Notable Models

a. Fair-Rite Ferrite Cores

Fair-Rite is a well-known manufacturer of ferrite cores and inductors. Their products are widely used in various applications, including telecommunications and consumer electronics. Fair-Rite ferrite cores are known for their high quality and reliability.

b. TDK Ferrite Beads

TDK is another leading manufacturer of ferrite components. Their ferrite beads are commonly used for noise suppression in electronic circuits. TDK's ferrite beads are designed to provide excellent attenuation of high-frequency noise while maintaining low DC resistance.

B. Iron Powder Inductors

1. Characteristics of Iron Powder Cores

Iron powder cores are made from finely powdered iron particles that are compacted and sintered. They offer excellent saturation characteristics and are suitable for applications requiring high current handling.

2. Notable Models

a. Micrometals Iron Powder Cores

Micrometals is a prominent manufacturer of iron powder cores. Their products are known for their high efficiency and low losses, making them ideal for power supply applications.

b. Amidon Iron Powder Inductors

Amidon is another reputable manufacturer of iron powder inductors. Their inductors are widely used in RF applications and are known for their reliability and performance.

C. Composite Core Inductors

1. Benefits of Composite Materials

Composite core inductors combine the advantages of ferrite and iron powder materials. They offer improved performance in terms of saturation current and thermal stability, making them suitable for a wide range of applications.

2. Notable Models

a. EPCOS Composite Inductors

EPCOS, a subsidiary of TDK, produces a range of composite inductors known for their high efficiency and compact design. These inductors are widely used in power electronics and automotive applications.

b. Vishay Dale Composite Inductors

Vishay Dale is another leading manufacturer of composite inductors. Their products are known for their reliability and performance in demanding applications, including industrial and telecommunications.

IV. Comparison of Popular Models

A. Performance Metrics

1. Efficiency

Efficiency is a critical factor when comparing magnetic ring inductors. Higher efficiency means lower power losses, which is essential for applications where energy conservation is a priority.

2. Thermal Stability

Thermal stability is another important consideration. Inductors that can operate at higher temperatures without degradation in performance are preferred, especially in high-power applications.

B. Cost Considerations

Cost is always a factor in component selection. While high-performance inductors may come at a premium, the long-term benefits of efficiency and reliability can justify the investment.

C. Availability and Sourcing

Availability and sourcing are crucial for manufacturers. Popular models from reputable manufacturers are often easier to source, ensuring that production schedules are met without delays.

V. Trends in Magnetic Ring Inductor Technology

A. Advancements in Materials

Recent advancements in materials science have led to the development of new core materials that offer improved performance characteristics. These materials can enhance inductance values while reducing losses.

B. Miniaturization and Integration

As electronic devices become smaller and more compact, the trend towards miniaturization in inductors is becoming increasingly important. Manufacturers are developing smaller inductors that maintain high performance without compromising on efficiency.

C. Environmental Considerations

With growing awareness of environmental issues, manufacturers are focusing on producing inductors that are more environmentally friendly. This includes using sustainable materials and processes that reduce waste and energy consumption.

VI. Conclusion

A. Summary of Key Points

Magnetic ring inductors are essential components in modern electronics, offering efficient energy storage and minimal interference. Understanding the different types of inductors, their key parameters, and popular models can help engineers and designers make informed decisions.

B. Future Outlook for Magnetic Ring Inductors

The future of magnetic ring inductors looks promising, with ongoing advancements in materials and technology. As the demand for efficient and compact inductors continues to grow, manufacturers will likely focus on innovation to meet these needs.

C. Final Thoughts on Choosing the Right Inductor Model

When selecting a magnetic ring inductor, it is essential to consider factors such as inductance, saturation current, DC resistance, and application requirements. By understanding the various models available and their performance characteristics, designers can choose the right inductor for their specific needs.

VII. References

A. Academic Journals

- IEEE Transactions on Power Electronics

- Journal of Applied Physics

B. Industry Reports

- Market Research Reports on Inductor Technologies

- Industry Analysis on Passive Components

C. Manufacturer Specifications and Datasheets

- Fair-Rite Products Corp. Datasheets

- TDK Corporation Product Catalogs

This comprehensive exploration of magnetic ring inductors provides valuable insights into their importance, popular models, and future trends, equipping readers with the knowledge needed to make informed decisions in their electronic designs.