What are the Popular Capacitor Capacity Product Types?

I. Introduction

Capacitors are fundamental components in electronic circuits, serving as energy storage devices that can release energy when needed. They play a crucial role in various applications, from filtering signals to stabilizing voltage and providing power during brief interruptions. Understanding the different types of capacitors and their capacities is essential for anyone involved in electronics, whether you're a hobbyist, engineer, or student. This article aims to provide an overview of popular capacitor capacity product types, their applications, and factors to consider when selecting the right capacitor for your needs.

II. Understanding Capacitor Capacity

A. Explanation of Capacitance

Capacitance is the ability of a capacitor to store electrical energy in an electric field. It is defined as the ratio of the electric charge stored on one plate of the capacitor to the voltage across the plates. The unit of capacitance is the Farad (F), but in practical applications, capacitors are often measured in microfarads (µF), nanofarads (nF), or picofarads (pF).

1. **Definition and Units**:

- **Farad (F)**: A large unit of capacitance, typically used for supercapacitors.

- **Microfarad (µF)**: Commonly used in audio and power applications.

- **Nanofarad (nF)**: Often used in RF applications.

- **Picofarad (pF)**: Used in high-frequency applications.

2. **Factors Affecting Capacitance**:

- The surface area of the plates: Larger plates can store more charge.

- The distance between the plates: Closer plates increase capacitance.

- The dielectric material: Different materials have different dielectric constants, affecting capacitance.

B. Role of Capacitance in Electronic Applications

Capacitance is critical in various electronic applications, including timing circuits, power supply smoothing, and signal coupling. The choice of capacitance value can significantly impact the performance of a circuit, making it essential to understand the requirements of your specific application.

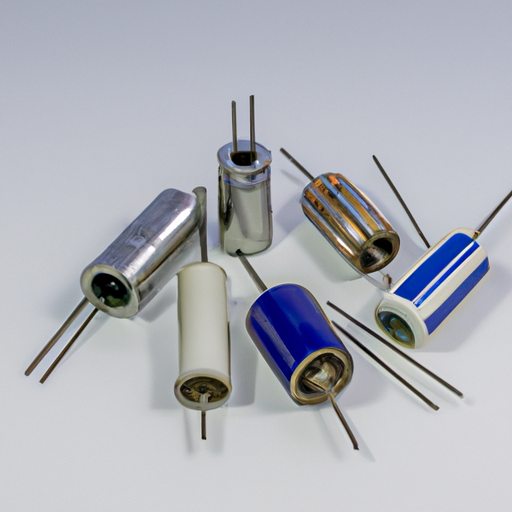

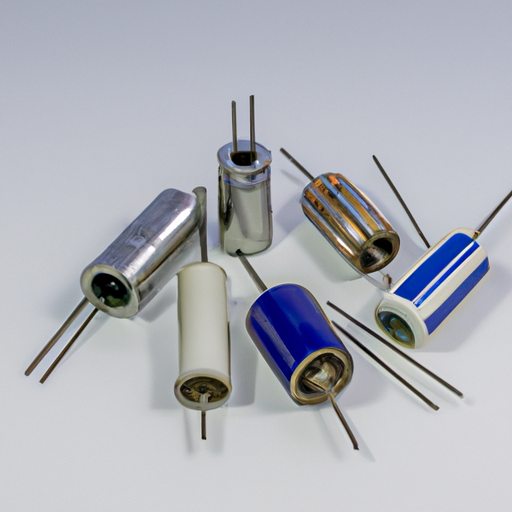

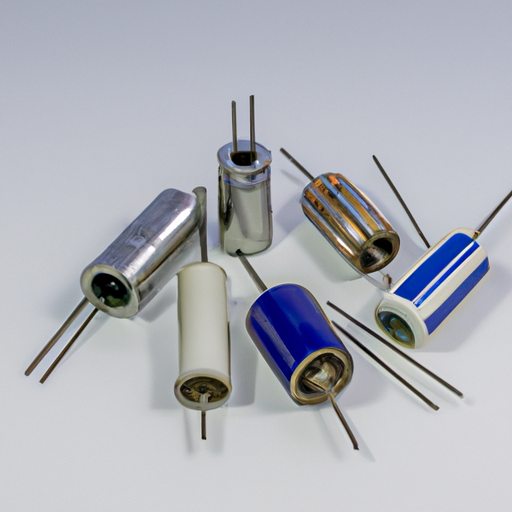

III. Types of Capacitors

Capacitors come in various types, each with unique characteristics and applications. Here’s an overview of some of the most common types:

A. Overview of Different Capacitor Types

1. **Ceramic Capacitors**:

- Made from ceramic materials, these capacitors are widely used due to their small size and reliability. They are available in various capacitance values and voltage ratings, making them suitable for high-frequency applications.

2. **Electrolytic Capacitors**:

- These capacitors use an electrolyte to achieve a larger capacitance in a smaller volume. They are polarized, meaning they have a positive and negative terminal, and are commonly used in power supply circuits.

3. **Film Capacitors**:

- Made from thin plastic films, these capacitors are known for their stability and low loss. They are often used in audio applications and power electronics.

4. **Tantalum Capacitors**:

- Similar to electrolytic capacitors but made from tantalum metal, these capacitors offer high capacitance in a small package. They are often used in compact electronic devices.

5. **Supercapacitors**:

- Also known as ultracapacitors, these devices can store a significant amount of energy and are used in applications requiring rapid charge and discharge cycles, such as energy storage systems.

6. **Mica Capacitors**:

- Known for their high precision and stability, mica capacitors are often used in RF applications and high-frequency circuits.

7. **Aluminum and Tantalum Electrolytic Capacitors**:

- These are specific types of electrolytic capacitors that use aluminum or tantalum as the anode material, providing different characteristics suitable for various applications.

IV. Popular Capacitor Capacity Ranges

Capacitors are categorized based on their capacitance values, which can be broadly classified into three ranges: low, medium, and high capacity.

A. Low-Capacity Capacitors (pF to µF)

1. **Applications and Examples**:

- Low-capacity capacitors are often used in timing circuits, coupling and decoupling applications, and high-frequency signal processing.

2. **Common Types Used**:

- Ceramic and film capacitors are prevalent in this range due to their stability and reliability.

B. Medium-Capacity Capacitors (µF to mF)

1. **Applications and Examples**:

- These capacitors are commonly found in power supply circuits, audio equipment, and motor start applications.

2. **Common Types Used**:

- Electrolytic and film capacitors are frequently used in this range, providing a balance between size and capacitance.

C. High-Capacity Capacitors (mF to F)

1. **Applications and Examples**:

- High-capacity capacitors are used in energy storage systems, electric vehicles, and applications requiring rapid charge and discharge cycles.

2. **Common Types Used**:

- Supercapacitors and large electrolytic capacitors are typical in this category, offering significant energy storage capabilities.

V. Factors Influencing Capacitor Selection

When selecting a capacitor for a specific application, several factors must be considered:

A. Voltage Rating

The voltage rating indicates the maximum voltage the capacitor can handle without breaking down. It is crucial to choose a capacitor with a voltage rating higher than the maximum voltage it will encounter in the circuit.

B. Temperature Coefficient

Capacitors can change their capacitance with temperature variations. Understanding the temperature coefficient helps ensure stable performance in varying environmental conditions.

C. Equivalent Series Resistance (ESR)

ESR is a measure of the resistance encountered by the current flowing through the capacitor. Low ESR is desirable in applications where high-frequency performance is critical.

D. Size and Form Factor

The physical size and shape of the capacitor can impact its suitability for specific applications, especially in compact electronic devices.

E. Application-Specific Requirements

Different applications may have unique requirements, such as low leakage current, high ripple current capability, or specific frequency response characteristics.

VI. Applications of Different Capacitor Types

Capacitors are used in a wide range of applications across various industries:

A. Consumer Electronics

In devices like smartphones, tablets, and televisions, capacitors are used for power supply filtering, signal coupling, and timing applications.

B. Industrial Applications

Capacitors play a vital role in motor control, power factor correction, and energy storage systems in industrial settings.

C. Automotive Electronics

Modern vehicles rely on capacitors for various functions, including power management, audio systems, and safety features.

D. Renewable Energy Systems

Capacitors are essential in solar inverters and energy storage systems, helping to manage power flow and stabilize voltage.

E. Telecommunications

In telecommunications, capacitors are used in signal processing, filtering, and power supply applications to ensure reliable communication.

VII. Future Trends in Capacitor Technology

As technology advances, the demand for more efficient and compact capacitors continues to grow. Some future trends include:

A. Advancements in Materials and Manufacturing

New materials and manufacturing techniques are being developed to create capacitors with higher capacitance values, lower ESR, and improved thermal stability.

B. Increasing Demand for Energy-Efficient Components

With the push for energy efficiency in electronics, capacitors that minimize energy loss and improve performance are becoming increasingly important.

C. The Role of Capacitors in Emerging Technologies

Capacitors will play a crucial role in emerging technologies such as electric vehicles, IoT devices, and renewable energy systems, where energy storage and management are critical.

VIII. Conclusion

Understanding the different types of capacitors and their capacities is essential for anyone involved in electronics. From low-capacity ceramic capacitors to high-capacity supercapacitors, each type has its unique applications and characteristics. When selecting a capacitor, it is crucial to consider factors such as voltage rating, temperature coefficient, and application-specific requirements. As technology continues to evolve, staying informed about advancements in capacitor technology will be vital for optimizing electronic designs and applications.

IX. References

For further reading and resources on capacitors and their applications, consider exploring the following:

1. "Capacitors: Principles and Applications" by John Smith

2. "The Art of Electronics" by Paul Horowitz and Winfield Hill

3. Online resources such as educational websites, electronics forums, and manufacturer datasheets.

By delving deeper into the world of capacitors, you can enhance your understanding and application of these essential electronic components.

What are the Popular Capacitor Capacity Product Types?

I. Introduction

Capacitors are fundamental components in electronic circuits, serving as energy storage devices that can release energy when needed. They play a crucial role in various applications, from filtering signals to stabilizing voltage and providing power during brief interruptions. Understanding the different types of capacitors and their capacities is essential for anyone involved in electronics, whether you're a hobbyist, engineer, or student. This article aims to provide an overview of popular capacitor capacity product types, their applications, and factors to consider when selecting the right capacitor for your needs.

II. Understanding Capacitor Capacity

A. Explanation of Capacitance

Capacitance is the ability of a capacitor to store electrical energy in an electric field. It is defined as the ratio of the electric charge stored on one plate of the capacitor to the voltage across the plates. The unit of capacitance is the Farad (F), but in practical applications, capacitors are often measured in microfarads (µF), nanofarads (nF), or picofarads (pF).

1. **Definition and Units**:

- **Farad (F)**: A large unit of capacitance, typically used for supercapacitors.

- **Microfarad (µF)**: Commonly used in audio and power applications.

- **Nanofarad (nF)**: Often used in RF applications.

- **Picofarad (pF)**: Used in high-frequency applications.

2. **Factors Affecting Capacitance**:

- The surface area of the plates: Larger plates can store more charge.

- The distance between the plates: Closer plates increase capacitance.

- The dielectric material: Different materials have different dielectric constants, affecting capacitance.

B. Role of Capacitance in Electronic Applications

Capacitance is critical in various electronic applications, including timing circuits, power supply smoothing, and signal coupling. The choice of capacitance value can significantly impact the performance of a circuit, making it essential to understand the requirements of your specific application.

III. Types of Capacitors

Capacitors come in various types, each with unique characteristics and applications. Here’s an overview of some of the most common types:

A. Overview of Different Capacitor Types

1. **Ceramic Capacitors**:

- Made from ceramic materials, these capacitors are widely used due to their small size and reliability. They are available in various capacitance values and voltage ratings, making them suitable for high-frequency applications.

2. **Electrolytic Capacitors**:

- These capacitors use an electrolyte to achieve a larger capacitance in a smaller volume. They are polarized, meaning they have a positive and negative terminal, and are commonly used in power supply circuits.

3. **Film Capacitors**:

- Made from thin plastic films, these capacitors are known for their stability and low loss. They are often used in audio applications and power electronics.

4. **Tantalum Capacitors**:

- Similar to electrolytic capacitors but made from tantalum metal, these capacitors offer high capacitance in a small package. They are often used in compact electronic devices.

5. **Supercapacitors**:

- Also known as ultracapacitors, these devices can store a significant amount of energy and are used in applications requiring rapid charge and discharge cycles, such as energy storage systems.

6. **Mica Capacitors**:

- Known for their high precision and stability, mica capacitors are often used in RF applications and high-frequency circuits.

7. **Aluminum and Tantalum Electrolytic Capacitors**:

- These are specific types of electrolytic capacitors that use aluminum or tantalum as the anode material, providing different characteristics suitable for various applications.

IV. Popular Capacitor Capacity Ranges

Capacitors are categorized based on their capacitance values, which can be broadly classified into three ranges: low, medium, and high capacity.

A. Low-Capacity Capacitors (pF to µF)

1. **Applications and Examples**:

- Low-capacity capacitors are often used in timing circuits, coupling and decoupling applications, and high-frequency signal processing.

2. **Common Types Used**:

- Ceramic and film capacitors are prevalent in this range due to their stability and reliability.

B. Medium-Capacity Capacitors (µF to mF)

1. **Applications and Examples**:

- These capacitors are commonly found in power supply circuits, audio equipment, and motor start applications.

2. **Common Types Used**:

- Electrolytic and film capacitors are frequently used in this range, providing a balance between size and capacitance.

C. High-Capacity Capacitors (mF to F)

1. **Applications and Examples**:

- High-capacity capacitors are used in energy storage systems, electric vehicles, and applications requiring rapid charge and discharge cycles.

2. **Common Types Used**:

- Supercapacitors and large electrolytic capacitors are typical in this category, offering significant energy storage capabilities.

V. Factors Influencing Capacitor Selection

When selecting a capacitor for a specific application, several factors must be considered:

A. Voltage Rating

The voltage rating indicates the maximum voltage the capacitor can handle without breaking down. It is crucial to choose a capacitor with a voltage rating higher than the maximum voltage it will encounter in the circuit.

B. Temperature Coefficient

Capacitors can change their capacitance with temperature variations. Understanding the temperature coefficient helps ensure stable performance in varying environmental conditions.

C. Equivalent Series Resistance (ESR)

ESR is a measure of the resistance encountered by the current flowing through the capacitor. Low ESR is desirable in applications where high-frequency performance is critical.

D. Size and Form Factor

The physical size and shape of the capacitor can impact its suitability for specific applications, especially in compact electronic devices.

E. Application-Specific Requirements

Different applications may have unique requirements, such as low leakage current, high ripple current capability, or specific frequency response characteristics.

VI. Applications of Different Capacitor Types

Capacitors are used in a wide range of applications across various industries:

A. Consumer Electronics

In devices like smartphones, tablets, and televisions, capacitors are used for power supply filtering, signal coupling, and timing applications.

B. Industrial Applications

Capacitors play a vital role in motor control, power factor correction, and energy storage systems in industrial settings.

C. Automotive Electronics

Modern vehicles rely on capacitors for various functions, including power management, audio systems, and safety features.

D. Renewable Energy Systems

Capacitors are essential in solar inverters and energy storage systems, helping to manage power flow and stabilize voltage.

E. Telecommunications

In telecommunications, capacitors are used in signal processing, filtering, and power supply applications to ensure reliable communication.

VII. Future Trends in Capacitor Technology

As technology advances, the demand for more efficient and compact capacitors continues to grow. Some future trends include:

A. Advancements in Materials and Manufacturing

New materials and manufacturing techniques are being developed to create capacitors with higher capacitance values, lower ESR, and improved thermal stability.

B. Increasing Demand for Energy-Efficient Components

With the push for energy efficiency in electronics, capacitors that minimize energy loss and improve performance are becoming increasingly important.

C. The Role of Capacitors in Emerging Technologies

Capacitors will play a crucial role in emerging technologies such as electric vehicles, IoT devices, and renewable energy systems, where energy storage and management are critical.

VIII. Conclusion

Understanding the different types of capacitors and their capacities is essential for anyone involved in electronics. From low-capacity ceramic capacitors to high-capacity supercapacitors, each type has its unique applications and characteristics. When selecting a capacitor, it is crucial to consider factors such as voltage rating, temperature coefficient, and application-specific requirements. As technology continues to evolve, staying informed about advancements in capacitor technology will be vital for optimizing electronic designs and applications.

IX. References

For further reading and resources on capacitors and their applications, consider exploring the following:

1. "Capacitors: Principles and Applications" by John Smith

2. "The Art of Electronics" by Paul Horowitz and Winfield Hill

3. Online resources such as educational websites, electronics forums, and manufacturer datasheets.

By delving deeper into the world of capacitors, you can enhance your understanding and application of these essential electronic components.