Understanding Wirewound Inductors

I. Introduction

In the realm of electronics, inductors play a crucial role in the functioning of various circuits. Among the different types of inductors, wirewound inductors stand out due to their unique construction and performance characteristics. This article aims to provide a comprehensive understanding of wirewound inductors, their significance in electronic applications, and the factors to consider when selecting the right inductor for your needs.

II. Basic Concepts of Inductance

A. Explanation of Inductance

Inductance is a fundamental property of electrical circuits that describes the ability of a conductor to store energy in a magnetic field when an electric current flows through it. The unit of inductance is the Henry (H), named after the American scientist Joseph Henry. Inductance plays a vital role in various applications, including energy storage, filtering, and signal processing.

B. Types of Inductors

Inductors come in various forms, each suited for specific applications. The three primary types of inductors include:

1. **Air Core Inductors**: These inductors do not use a magnetic core, relying solely on the air surrounding the wire to create inductance. They are typically used in high-frequency applications due to their low losses.

2. **Ferrite Core Inductors**: Ferrite core inductors utilize a magnetic core made of ferrite material, which enhances inductance and reduces losses. They are commonly used in power supply circuits and RF applications.

3. **Wirewound Inductors**: As the name suggests, wirewound inductors are constructed by winding a wire around a core material. This design allows for higher inductance values and better performance in various applications.

III. What is a Wirewound Inductor?

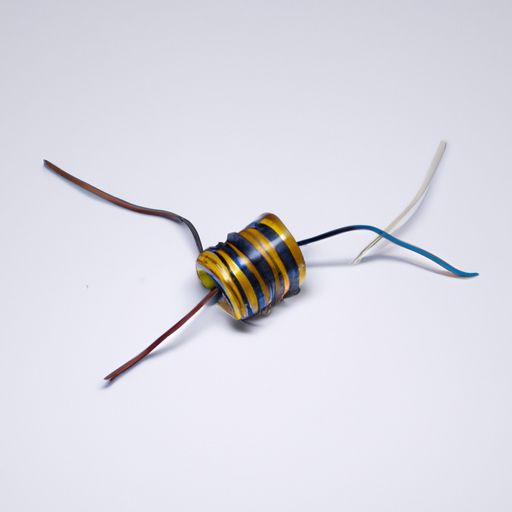

A. Construction and Materials

Wirewound inductors are characterized by their construction, which typically involves winding a conductive wire around a core. The materials used in their construction include:

1. **Wire Types**: Copper is the most common wire material due to its excellent conductivity, but aluminum and other materials may also be used depending on the application.

2. **Core Materials**: Wirewound inductors can have air cores or magnetic cores made from ferrite or other materials. The choice of core material affects the inductor's performance characteristics.

B. How Wirewound Inductors are Made

The manufacturing process of wirewound inductors involves several steps:

1. **Winding Process**: The wire is wound around the core in a specific pattern to achieve the desired inductance value. The number of turns and the spacing between them are critical factors in determining the inductor's performance.

2. **Insulation and Coating**: After winding, the inductor is often coated with an insulating material to prevent short circuits and enhance durability. This coating can also provide additional protection against environmental factors.

C. Characteristics of Wirewound Inductors

Wirewound inductors exhibit several key characteristics:

1. **Inductance Value**: The inductance value is determined by the number of turns, the core material, and the geometry of the inductor. Wirewound inductors can achieve high inductance values, making them suitable for various applications.

2. **Resistance and Quality Factor (Q)**: The resistance of the wire affects the inductor's efficiency. The quality factor (Q) is a measure of the inductor's performance, with higher Q values indicating lower losses and better performance.

3. **Saturation Current**: This is the maximum current the inductor can handle before the core material becomes saturated, leading to a decrease in inductance. Understanding saturation current is crucial for ensuring reliable operation in circuits.

IV. Working Principle of Wirewound Inductors

A. Electromagnetic Induction

Wirewound inductors operate based on the principle of electromagnetic induction. When an electric current flows through the wire, it generates a magnetic field around it. This magnetic field induces a voltage in the wire itself, opposing changes in current according to Lenz's Law.

B. Behavior in AC and DC Circuits

In DC circuits, wirewound inductors initially resist changes in current, allowing them to store energy in the magnetic field. Once the current stabilizes, the inductor behaves like a short circuit. In AC circuits, wirewound inductors continuously oppose changes in current, resulting in reactance that affects the overall impedance of the circuit.

C. Impedance and Reactance

The impedance of a wirewound inductor is a combination of its resistance and reactance. Reactance is the opposition to alternating current due to inductance, and it increases with frequency. Understanding the impedance characteristics of wirewound inductors is essential for designing effective circuits.

V. Applications of Wirewound Inductors

Wirewound inductors find applications in various fields, including:

A. Power Supply Circuits

In power supply circuits, wirewound inductors are used for energy storage, filtering, and voltage regulation. They help smooth out voltage fluctuations and provide stable power to electronic components.

B. RF Applications

In radio frequency (RF) applications, wirewound inductors are used in tuning circuits, oscillators, and filters. Their ability to handle high frequencies makes them ideal for RF signal processing.

C. Audio Equipment

Wirewound inductors are commonly found in audio equipment, where they are used in crossover networks and amplifiers to filter out unwanted frequencies and enhance sound quality.

D. Filters and Oscillators

Wirewound inductors are essential components in various filter designs, including low-pass, high-pass, and band-pass filters. They are also used in oscillators to generate specific frequencies.

E. Transformers and Chokes

Wirewound inductors are used in transformers to transfer energy between circuits and in chokes to limit current flow in specific parts of a circuit.

VI. Advantages and Disadvantages of Wirewound Inductors

A. Advantages

1. **High Inductance Values**: Wirewound inductors can achieve high inductance values, making them suitable for applications requiring significant energy storage.

2. **Good Performance at High Frequencies**: Their design allows for effective performance in high-frequency applications, making them ideal for RF and audio circuits.

3. **Customizability**: Wirewound inductors can be tailored to meet specific requirements, including inductance value, size, and core material.

B. Disadvantages

1. **Size and Weight Considerations**: Wirewound inductors can be larger and heavier than other types of inductors, which may be a drawback in compact electronic designs.

2. **Heat Generation**: Due to resistance in the wire, wirewound inductors can generate heat during operation, which may require additional cooling measures in high-power applications.

3. **Limited Current Handling in Some Designs**: Some wirewound inductors may have limitations in current handling, necessitating careful selection for specific applications.

VII. Selecting the Right Wirewound Inductor

A. Factors to Consider

When selecting a wirewound inductor, several factors should be taken into account:

1. **Inductance Value**: Determine the required inductance value for your application, considering the circuit's operating frequency and performance requirements.

2. **Current Rating**: Ensure the inductor can handle the expected current without exceeding its saturation current rating.

3. **Frequency Response**: Consider the frequency range of your application and select an inductor that performs well within that range.

4. **Physical Size and Mounting Options**: Evaluate the available space in your design and choose an inductor that fits your physical constraints.

B. Common Specifications and Standards

Familiarize yourself with common specifications and industry standards for inductors, such as those set by the Institute of Electrical and Electronics Engineers (IEEE) and the Electronic Industries Alliance (EIA). These standards can guide you in selecting high-quality components.

VIII. Conclusion

Wirewound inductors are essential components in modern electronic circuits, offering high inductance values and excellent performance in various applications. Understanding their construction, working principles, and characteristics is crucial for selecting the right inductor for your needs. As technology continues to evolve, wirewound inductors will remain a vital part of electronic design, with ongoing advancements in materials and manufacturing processes. We encourage you to explore further applications and designs to fully leverage the potential of wirewound inductors in your projects.

IX. References

For further reading and resources on wirewound inductors and inductance, consider the following:

1. "Inductors and Transformers for Power Electronics" by W. G. Hurley and W. H. Spangler.

2. IEEE Standards for Inductors and Magnetic Components.

3. Electronic Industries Alliance (EIA) guidelines for inductor specifications.

By delving into these resources, you can deepen your understanding of wirewound inductors and their applications in the ever-evolving field of electronics.

Understanding Wirewound Inductors

I. Introduction

In the realm of electronics, inductors play a crucial role in the functioning of various circuits. Among the different types of inductors, wirewound inductors stand out due to their unique construction and performance characteristics. This article aims to provide a comprehensive understanding of wirewound inductors, their significance in electronic applications, and the factors to consider when selecting the right inductor for your needs.

II. Basic Concepts of Inductance

A. Explanation of Inductance

Inductance is a fundamental property of electrical circuits that describes the ability of a conductor to store energy in a magnetic field when an electric current flows through it. The unit of inductance is the Henry (H), named after the American scientist Joseph Henry. Inductance plays a vital role in various applications, including energy storage, filtering, and signal processing.

B. Types of Inductors

Inductors come in various forms, each suited for specific applications. The three primary types of inductors include:

1. **Air Core Inductors**: These inductors do not use a magnetic core, relying solely on the air surrounding the wire to create inductance. They are typically used in high-frequency applications due to their low losses.

2. **Ferrite Core Inductors**: Ferrite core inductors utilize a magnetic core made of ferrite material, which enhances inductance and reduces losses. They are commonly used in power supply circuits and RF applications.

3. **Wirewound Inductors**: As the name suggests, wirewound inductors are constructed by winding a wire around a core material. This design allows for higher inductance values and better performance in various applications.

III. What is a Wirewound Inductor?

A. Construction and Materials

Wirewound inductors are characterized by their construction, which typically involves winding a conductive wire around a core. The materials used in their construction include:

1. **Wire Types**: Copper is the most common wire material due to its excellent conductivity, but aluminum and other materials may also be used depending on the application.

2. **Core Materials**: Wirewound inductors can have air cores or magnetic cores made from ferrite or other materials. The choice of core material affects the inductor's performance characteristics.

B. How Wirewound Inductors are Made

The manufacturing process of wirewound inductors involves several steps:

1. **Winding Process**: The wire is wound around the core in a specific pattern to achieve the desired inductance value. The number of turns and the spacing between them are critical factors in determining the inductor's performance.

2. **Insulation and Coating**: After winding, the inductor is often coated with an insulating material to prevent short circuits and enhance durability. This coating can also provide additional protection against environmental factors.

C. Characteristics of Wirewound Inductors

Wirewound inductors exhibit several key characteristics:

1. **Inductance Value**: The inductance value is determined by the number of turns, the core material, and the geometry of the inductor. Wirewound inductors can achieve high inductance values, making them suitable for various applications.

2. **Resistance and Quality Factor (Q)**: The resistance of the wire affects the inductor's efficiency. The quality factor (Q) is a measure of the inductor's performance, with higher Q values indicating lower losses and better performance.

3. **Saturation Current**: This is the maximum current the inductor can handle before the core material becomes saturated, leading to a decrease in inductance. Understanding saturation current is crucial for ensuring reliable operation in circuits.

IV. Working Principle of Wirewound Inductors

A. Electromagnetic Induction

Wirewound inductors operate based on the principle of electromagnetic induction. When an electric current flows through the wire, it generates a magnetic field around it. This magnetic field induces a voltage in the wire itself, opposing changes in current according to Lenz's Law.

B. Behavior in AC and DC Circuits

In DC circuits, wirewound inductors initially resist changes in current, allowing them to store energy in the magnetic field. Once the current stabilizes, the inductor behaves like a short circuit. In AC circuits, wirewound inductors continuously oppose changes in current, resulting in reactance that affects the overall impedance of the circuit.

C. Impedance and Reactance

The impedance of a wirewound inductor is a combination of its resistance and reactance. Reactance is the opposition to alternating current due to inductance, and it increases with frequency. Understanding the impedance characteristics of wirewound inductors is essential for designing effective circuits.

V. Applications of Wirewound Inductors

Wirewound inductors find applications in various fields, including:

A. Power Supply Circuits

In power supply circuits, wirewound inductors are used for energy storage, filtering, and voltage regulation. They help smooth out voltage fluctuations and provide stable power to electronic components.

B. RF Applications

In radio frequency (RF) applications, wirewound inductors are used in tuning circuits, oscillators, and filters. Their ability to handle high frequencies makes them ideal for RF signal processing.

C. Audio Equipment

Wirewound inductors are commonly found in audio equipment, where they are used in crossover networks and amplifiers to filter out unwanted frequencies and enhance sound quality.

D. Filters and Oscillators

Wirewound inductors are essential components in various filter designs, including low-pass, high-pass, and band-pass filters. They are also used in oscillators to generate specific frequencies.

E. Transformers and Chokes

Wirewound inductors are used in transformers to transfer energy between circuits and in chokes to limit current flow in specific parts of a circuit.

VI. Advantages and Disadvantages of Wirewound Inductors

A. Advantages

1. **High Inductance Values**: Wirewound inductors can achieve high inductance values, making them suitable for applications requiring significant energy storage.

2. **Good Performance at High Frequencies**: Their design allows for effective performance in high-frequency applications, making them ideal for RF and audio circuits.

3. **Customizability**: Wirewound inductors can be tailored to meet specific requirements, including inductance value, size, and core material.

B. Disadvantages

1. **Size and Weight Considerations**: Wirewound inductors can be larger and heavier than other types of inductors, which may be a drawback in compact electronic designs.

2. **Heat Generation**: Due to resistance in the wire, wirewound inductors can generate heat during operation, which may require additional cooling measures in high-power applications.

3. **Limited Current Handling in Some Designs**: Some wirewound inductors may have limitations in current handling, necessitating careful selection for specific applications.

VII. Selecting the Right Wirewound Inductor

A. Factors to Consider

When selecting a wirewound inductor, several factors should be taken into account:

1. **Inductance Value**: Determine the required inductance value for your application, considering the circuit's operating frequency and performance requirements.

2. **Current Rating**: Ensure the inductor can handle the expected current without exceeding its saturation current rating.

3. **Frequency Response**: Consider the frequency range of your application and select an inductor that performs well within that range.

4. **Physical Size and Mounting Options**: Evaluate the available space in your design and choose an inductor that fits your physical constraints.

B. Common Specifications and Standards

Familiarize yourself with common specifications and industry standards for inductors, such as those set by the Institute of Electrical and Electronics Engineers (IEEE) and the Electronic Industries Alliance (EIA). These standards can guide you in selecting high-quality components.

VIII. Conclusion

Wirewound inductors are essential components in modern electronic circuits, offering high inductance values and excellent performance in various applications. Understanding their construction, working principles, and characteristics is crucial for selecting the right inductor for your needs. As technology continues to evolve, wirewound inductors will remain a vital part of electronic design, with ongoing advancements in materials and manufacturing processes. We encourage you to explore further applications and designs to fully leverage the potential of wirewound inductors in your projects.

IX. References

For further reading and resources on wirewound inductors and inductance, consider the following:

1. "Inductors and Transformers for Power Electronics" by W. G. Hurley and W. H. Spangler.

2. IEEE Standards for Inductors and Magnetic Components.

3. Electronic Industries Alliance (EIA) guidelines for inductor specifications.

By delving into these resources, you can deepen your understanding of wirewound inductors and their applications in the ever-evolving field of electronics.