Latest Washing Machine Capacitor Specifications

I. Introduction

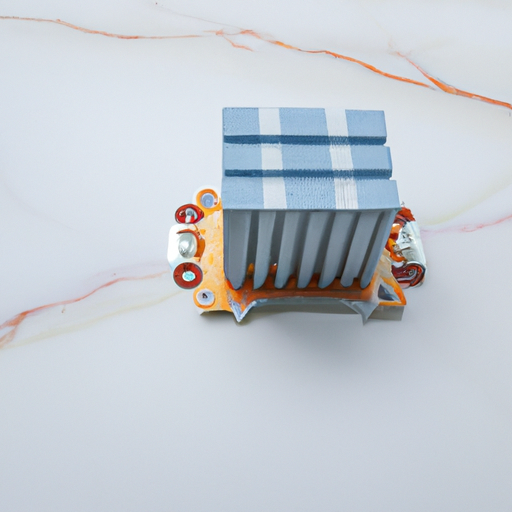

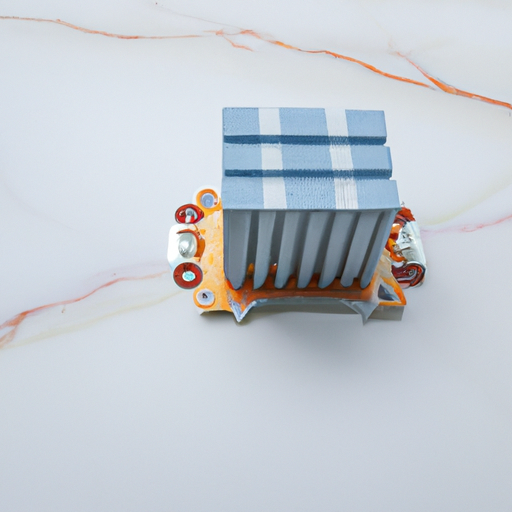

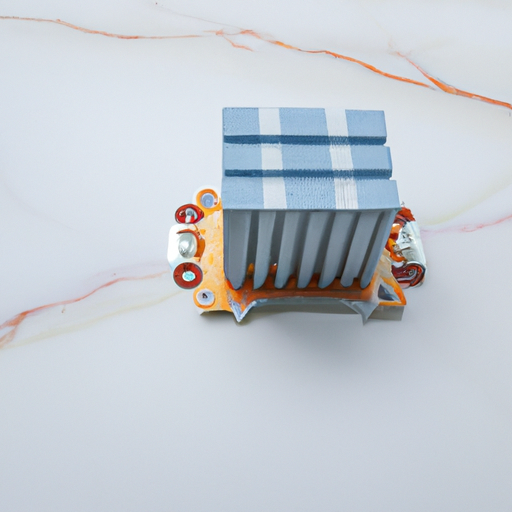

Washing machines are an essential appliance in modern households, making laundry tasks more efficient and convenient. At the heart of these machines lies a crucial component: the capacitor. Capacitors play a vital role in the operation of washing machines, particularly in the functioning of their motors. This article aims to provide a comprehensive overview of the latest washing machine capacitor specifications, exploring their types, key specifications, recent advancements in technology, and tips for selecting and maintaining them.

II. Understanding Capacitors in Washing Machines

A. Definition and Function of Capacitors

A capacitor is an electrical component that stores and releases energy. In washing machines, capacitors are primarily used to manage the operation of the motor. They provide the necessary starting torque to the motor, allowing it to initiate movement. Additionally, capacitors help regulate the motor's performance, ensuring smooth operation and energy efficiency.

1. Role in Motor Operation

When a washing machine is powered on, the capacitor provides a boost of energy to the motor, enabling it to start quickly. This initial surge is crucial for overcoming inertia and getting the drum moving. Once the motor is running, the capacitor continues to play a role in maintaining the motor's efficiency and performance.

2. Impact on Energy Efficiency

Capacitors contribute to the overall energy efficiency of washing machines. By ensuring that the motor operates smoothly and effectively, they help reduce energy consumption. This is particularly important in today's environmentally conscious world, where energy efficiency is a key consideration for consumers.

B. Types of Capacitors Used in Washing Machines

There are three main types of capacitors used in washing machines:

1. Start Capacitors

Start capacitors provide the initial boost of energy needed to start the motor. They are typically used in single-phase motors and are designed to disconnect from the circuit once the motor reaches a certain speed.

2. Run Capacitors

Run capacitors remain in the circuit while the motor is running. They help improve the motor's efficiency and performance by providing a continuous supply of energy.

3. Dual-Run Capacitors

Dual-run capacitors combine the functions of both start and run capacitors. They are commonly used in washing machines with more complex motor systems, providing both the initial boost and ongoing support for efficient operation.

III. Key Specifications of Washing Machine Capacitors

When selecting a capacitor for a washing machine, several key specifications must be considered:

A. Voltage Ratings

1. Common Voltage Ratings

Capacitors come with various voltage ratings, with common values being 120V and 240V. It is essential to choose a capacitor that matches the voltage requirements of the washing machine to ensure safe and effective operation.

2. Importance of Matching Voltage Ratings

Using a capacitor with an incorrect voltage rating can lead to failure or damage to the washing machine. Therefore, it is crucial to verify the voltage specifications before making a replacement.

B. Capacitance Values

1. Typical Capacitance Ranges

Capacitance is measured in microfarads (µF), and typical ranges for washing machine capacitors vary depending on the type and model of the machine. Start capacitors may range from 10µF to 100µF, while run capacitors typically range from 1µF to 50µF.

2. How Capacitance Affects Performance

The capacitance value directly impacts the performance of the motor. A capacitor with too low a capacitance may not provide enough starting torque, while one with too high a capacitance can lead to overheating and potential damage.

C. Temperature Ratings

1. Operating Temperature Ranges

Capacitors are rated for specific operating temperature ranges, typically between -40°C to 85°C (-40°F to 185°F). It is essential to select a capacitor that can withstand the temperature conditions in which the washing machine operates.

2. Effects of Temperature on Capacitor Lifespan

High temperatures can shorten the lifespan of a capacitor, leading to premature failure. Therefore, understanding the temperature ratings is crucial for ensuring long-term reliability.

D. Physical Dimensions

1. Size and Shape Considerations

Capacitors come in various sizes and shapes, which can affect their compatibility with specific washing machine models. It is essential to consider the physical dimensions when selecting a replacement capacitor.

2. Mounting Options and Compatibility

Different washing machines may have unique mounting requirements for capacitors. Ensuring that the selected capacitor is compatible with the machine's mounting options is vital for proper installation.

IV. Recent Advancements in Capacitor Technology

The field of capacitor technology has seen significant advancements in recent years, leading to improved performance and reliability.

A. Improved Materials and Construction

1. Use of High-Quality Dielectric Materials

Modern capacitors often utilize advanced dielectric materials that enhance their performance and durability. These materials can withstand higher temperatures and provide better energy storage capabilities.

2. Enhanced Durability and Reliability

With improved construction techniques, today's capacitors are designed to be more robust and reliable, reducing the likelihood of failure and extending their lifespan.

B. Energy Efficiency Improvements

1. Impact on Overall Washing Machine Performance

Advancements in capacitor technology have led to more energy-efficient washing machines. By optimizing the performance of the motor, these capacitors contribute to lower energy consumption and reduced utility bills.

2. Compliance with Energy Standards

Many modern washing machines equipped with advanced capacitors meet or exceed energy efficiency standards set by regulatory bodies, making them more appealing to environmentally conscious consumers.

C. Smart Technology Integration

1. Capacitors in Smart Washing Machines

As washing machines become smarter, capacitors play a crucial role in their operation. They help manage the energy demands of various smart features, ensuring efficient performance.

2. Role in Energy Management Systems

Capacitors are increasingly integrated into energy management systems, allowing washing machines to optimize their energy usage based on real-time data and user preferences.

V. Selecting the Right Capacitor for Washing Machines

Choosing the right capacitor for a washing machine involves several considerations:

A. Factors to Consider

1. Compatibility with Specific Washing Machine Models

It is essential to select a capacitor that is compatible with the specific model of the washing machine. This includes verifying voltage ratings, capacitance values, and physical dimensions.

2. Manufacturer Recommendations

Consulting the manufacturer's recommendations can provide valuable guidance in selecting the appropriate capacitor for a washing machine.

B. Common Brands and Their Specifications

1. Overview of Reputable Capacitor Manufacturers

Several reputable manufacturers produce high-quality capacitors for washing machines. Brands such as Siemens, Schneider Electric, and Panasonic are known for their reliable products.

2. Comparison of Specifications Across Brands

When selecting a capacitor, it is beneficial to compare specifications across different brands to find the best fit for a specific washing machine model.

VI. Maintenance and Troubleshooting

Proper maintenance and timely troubleshooting can extend the lifespan of washing machine capacitors.

A. Signs of Capacitor Failure

1. Symptoms to Watch for in Washing Machines

Common signs of capacitor failure include unusual noises, failure to start, or erratic motor behavior. If any of these symptoms occur, it may be time to inspect or replace the capacitor.

2. Importance of Timely Replacement

Addressing capacitor issues promptly can prevent further damage to the washing machine and ensure continued efficient operation.

B. Best Practices for Maintenance

1. Regular Inspections

Conducting regular inspections of the washing machine's components, including the capacitor, can help identify potential issues before they escalate.

2. Safe Handling and Installation Tips

When replacing a capacitor, it is essential to follow safety guidelines, including discharging the capacitor before handling and ensuring proper installation to avoid damage.

VII. Conclusion

Understanding the specifications of washing machine capacitors is crucial for ensuring optimal performance and longevity of the appliance. With advancements in technology, consumers can benefit from improved energy efficiency and reliability. Staying informed about the latest developments in capacitor technology can help users make informed decisions when selecting and maintaining their washing machines.

VIII. References

For further reading on washing machine capacitors and related topics, consider exploring the following sources:

1. Manufacturer specifications and guidelines

2. Industry standards for electrical components

3. Technical articles on capacitor technology advancements

By understanding the latest washing machine capacitor specifications, consumers can ensure their appliances operate efficiently and effectively, contributing to a more sustainable and cost-effective laundry experience.

Latest Washing Machine Capacitor Specifications

I. Introduction

Washing machines are an essential appliance in modern households, making laundry tasks more efficient and convenient. At the heart of these machines lies a crucial component: the capacitor. Capacitors play a vital role in the operation of washing machines, particularly in the functioning of their motors. This article aims to provide a comprehensive overview of the latest washing machine capacitor specifications, exploring their types, key specifications, recent advancements in technology, and tips for selecting and maintaining them.

II. Understanding Capacitors in Washing Machines

A. Definition and Function of Capacitors

A capacitor is an electrical component that stores and releases energy. In washing machines, capacitors are primarily used to manage the operation of the motor. They provide the necessary starting torque to the motor, allowing it to initiate movement. Additionally, capacitors help regulate the motor's performance, ensuring smooth operation and energy efficiency.

1. Role in Motor Operation

When a washing machine is powered on, the capacitor provides a boost of energy to the motor, enabling it to start quickly. This initial surge is crucial for overcoming inertia and getting the drum moving. Once the motor is running, the capacitor continues to play a role in maintaining the motor's efficiency and performance.

2. Impact on Energy Efficiency

Capacitors contribute to the overall energy efficiency of washing machines. By ensuring that the motor operates smoothly and effectively, they help reduce energy consumption. This is particularly important in today's environmentally conscious world, where energy efficiency is a key consideration for consumers.

B. Types of Capacitors Used in Washing Machines

There are three main types of capacitors used in washing machines:

1. Start Capacitors

Start capacitors provide the initial boost of energy needed to start the motor. They are typically used in single-phase motors and are designed to disconnect from the circuit once the motor reaches a certain speed.

2. Run Capacitors

Run capacitors remain in the circuit while the motor is running. They help improve the motor's efficiency and performance by providing a continuous supply of energy.

3. Dual-Run Capacitors

Dual-run capacitors combine the functions of both start and run capacitors. They are commonly used in washing machines with more complex motor systems, providing both the initial boost and ongoing support for efficient operation.

III. Key Specifications of Washing Machine Capacitors

When selecting a capacitor for a washing machine, several key specifications must be considered:

A. Voltage Ratings

1. Common Voltage Ratings

Capacitors come with various voltage ratings, with common values being 120V and 240V. It is essential to choose a capacitor that matches the voltage requirements of the washing machine to ensure safe and effective operation.

2. Importance of Matching Voltage Ratings

Using a capacitor with an incorrect voltage rating can lead to failure or damage to the washing machine. Therefore, it is crucial to verify the voltage specifications before making a replacement.

B. Capacitance Values

1. Typical Capacitance Ranges

Capacitance is measured in microfarads (µF), and typical ranges for washing machine capacitors vary depending on the type and model of the machine. Start capacitors may range from 10µF to 100µF, while run capacitors typically range from 1µF to 50µF.

2. How Capacitance Affects Performance

The capacitance value directly impacts the performance of the motor. A capacitor with too low a capacitance may not provide enough starting torque, while one with too high a capacitance can lead to overheating and potential damage.

C. Temperature Ratings

1. Operating Temperature Ranges

Capacitors are rated for specific operating temperature ranges, typically between -40°C to 85°C (-40°F to 185°F). It is essential to select a capacitor that can withstand the temperature conditions in which the washing machine operates.

2. Effects of Temperature on Capacitor Lifespan

High temperatures can shorten the lifespan of a capacitor, leading to premature failure. Therefore, understanding the temperature ratings is crucial for ensuring long-term reliability.

D. Physical Dimensions

1. Size and Shape Considerations

Capacitors come in various sizes and shapes, which can affect their compatibility with specific washing machine models. It is essential to consider the physical dimensions when selecting a replacement capacitor.

2. Mounting Options and Compatibility

Different washing machines may have unique mounting requirements for capacitors. Ensuring that the selected capacitor is compatible with the machine's mounting options is vital for proper installation.

IV. Recent Advancements in Capacitor Technology

The field of capacitor technology has seen significant advancements in recent years, leading to improved performance and reliability.

A. Improved Materials and Construction

1. Use of High-Quality Dielectric Materials

Modern capacitors often utilize advanced dielectric materials that enhance their performance and durability. These materials can withstand higher temperatures and provide better energy storage capabilities.

2. Enhanced Durability and Reliability

With improved construction techniques, today's capacitors are designed to be more robust and reliable, reducing the likelihood of failure and extending their lifespan.

B. Energy Efficiency Improvements

1. Impact on Overall Washing Machine Performance

Advancements in capacitor technology have led to more energy-efficient washing machines. By optimizing the performance of the motor, these capacitors contribute to lower energy consumption and reduced utility bills.

2. Compliance with Energy Standards

Many modern washing machines equipped with advanced capacitors meet or exceed energy efficiency standards set by regulatory bodies, making them more appealing to environmentally conscious consumers.

C. Smart Technology Integration

1. Capacitors in Smart Washing Machines

As washing machines become smarter, capacitors play a crucial role in their operation. They help manage the energy demands of various smart features, ensuring efficient performance.

2. Role in Energy Management Systems

Capacitors are increasingly integrated into energy management systems, allowing washing machines to optimize their energy usage based on real-time data and user preferences.

V. Selecting the Right Capacitor for Washing Machines

Choosing the right capacitor for a washing machine involves several considerations:

A. Factors to Consider

1. Compatibility with Specific Washing Machine Models

It is essential to select a capacitor that is compatible with the specific model of the washing machine. This includes verifying voltage ratings, capacitance values, and physical dimensions.

2. Manufacturer Recommendations

Consulting the manufacturer's recommendations can provide valuable guidance in selecting the appropriate capacitor for a washing machine.

B. Common Brands and Their Specifications

1. Overview of Reputable Capacitor Manufacturers

Several reputable manufacturers produce high-quality capacitors for washing machines. Brands such as Siemens, Schneider Electric, and Panasonic are known for their reliable products.

2. Comparison of Specifications Across Brands

When selecting a capacitor, it is beneficial to compare specifications across different brands to find the best fit for a specific washing machine model.

VI. Maintenance and Troubleshooting

Proper maintenance and timely troubleshooting can extend the lifespan of washing machine capacitors.

A. Signs of Capacitor Failure

1. Symptoms to Watch for in Washing Machines

Common signs of capacitor failure include unusual noises, failure to start, or erratic motor behavior. If any of these symptoms occur, it may be time to inspect or replace the capacitor.

2. Importance of Timely Replacement

Addressing capacitor issues promptly can prevent further damage to the washing machine and ensure continued efficient operation.

B. Best Practices for Maintenance

1. Regular Inspections

Conducting regular inspections of the washing machine's components, including the capacitor, can help identify potential issues before they escalate.

2. Safe Handling and Installation Tips

When replacing a capacitor, it is essential to follow safety guidelines, including discharging the capacitor before handling and ensuring proper installation to avoid damage.

VII. Conclusion

Understanding the specifications of washing machine capacitors is crucial for ensuring optimal performance and longevity of the appliance. With advancements in technology, consumers can benefit from improved energy efficiency and reliability. Staying informed about the latest developments in capacitor technology can help users make informed decisions when selecting and maintaining their washing machines.

VIII. References

For further reading on washing machine capacitors and related topics, consider exploring the following sources:

1. Manufacturer specifications and guidelines

2. Industry standards for electrical components

3. Technical articles on capacitor technology advancements

By understanding the latest washing machine capacitor specifications, consumers can ensure their appliances operate efficiently and effectively, contributing to a more sustainable and cost-effective laundry experience.